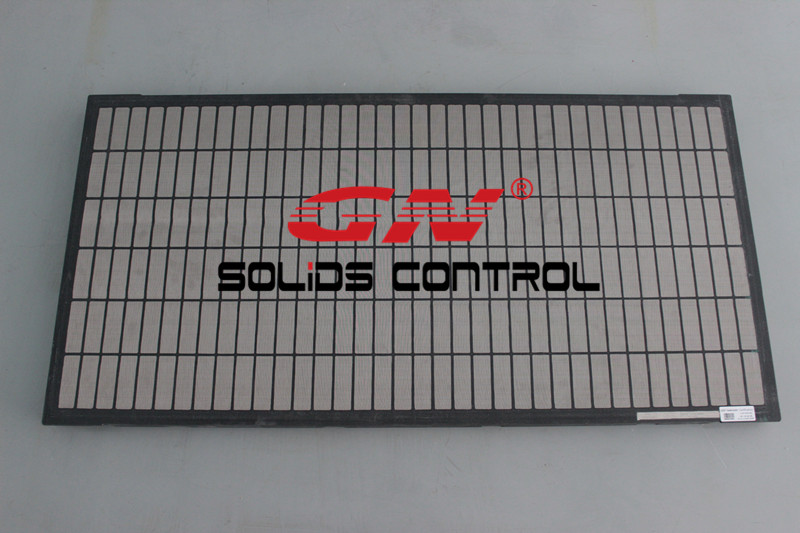

GN Solids Control now manufactures over five thousands of shaker screens every month in Langfang manufacturing plant. GN Solids Control shaker screens includes the following replacement shaker screens, like replacement screen for Mi-Swaco Mongoose, Derrick 500 and Derrick 2000, NOV King Cobra/ Cobra or VSM 300 and FSI screens etc.

Since 2013, GN Solids America LLC has been actively working in North America. More and more companies are getting to known GN Solids as one of the most famous solids control and waste management equipment provider. Now in GN Solids Houston warehouse, GN Solids has over more than 5000 pieces shaker screens. And some GN Solids Control treating equipment are also in stock, like shale shakers, desander, desilter, mud cleaner and decanter centrifuge. GN Cuttings Dryer also stocks in Houston warehouse.

During the last several weeks, GN Solids Control has built some high racks, so now GN Solids Control can stock more shaker screens.

As one of the shaker screen manufacturers, GN Solids Control manufactures various shaker screens. Many shaker screen users are using OEM screen before, but after they tried GN shaker screens they will only choose to use purchase from GN. Shaker screens are wearing parts, GN Solids Control got repeat order every week.

Now GN Solids America is looking for shaker screen distributors, if you are selling shaker screens right now in USA, Canada and Mexico or any countries from South America, welcome to connect with us and join GN as one partner. GN Solids Control has done some compare test with the other OEM screens, it turns out GN shaker screens are even than better than the OEM screens.

GN Solids Control also hired one USA third party to test all GN made shaker screens. Based on the test report, GN screens conform to API RP 13C standard.

- Details

-

Published: 28 September 2017

GN Solids Control has been providing decanter centrifuges to global customers for a long while. Every year, GN Solids Control manufactures over 500 sets of decanter centrifuges with some other solids and liquid separation equipment. In order to operate the centrifuge well, here are some thing we would like to share with you. Today

we will discuss the lubrication of GN centrifuge.

There are some key point need to be lubricated at a certain time: the 2 main bearings as well as the small end cover and large end cover bearings are very important.

Just take an example of the centrifuges that purchased by one USA customer:

1. How many grams of grease should the bearings get that are to be greased every 8 hours (listed as location 2 and 5 in the manuals)? This question is for both the

14" and 22" centrifuge we purchased.

According to our service engineer, every 8 hours you need to add 3~5 times grease by using the grease gun, so it is only around 3g~5g for each bearing. Another way to

judge whether the grease it enough is filling the grease until it overflows from the discharge port.

2. In both manuals it is noted that the symmetry jackscrews should be loosened before greasing the small and big end covers? What does this mean? Maybe it is

obvious when our technician is looking at the centrifuge, but I don't have the machine in front of me.

There are 2 jack bolts (red circular) on the ' Location3 small end cover. You need to loose and take off these 2 jack bolts (sequence not matter), and inject lubricate

from one point, when you see new lubricate come out from the other point, then the small end cover is totally replaced with new lubricate. Same as large end cover.

Anytime and anywhere, we can send our engineer to help customer set up the centrifuge and train their workers globally.

- Details

-

Published: 21 September 2017

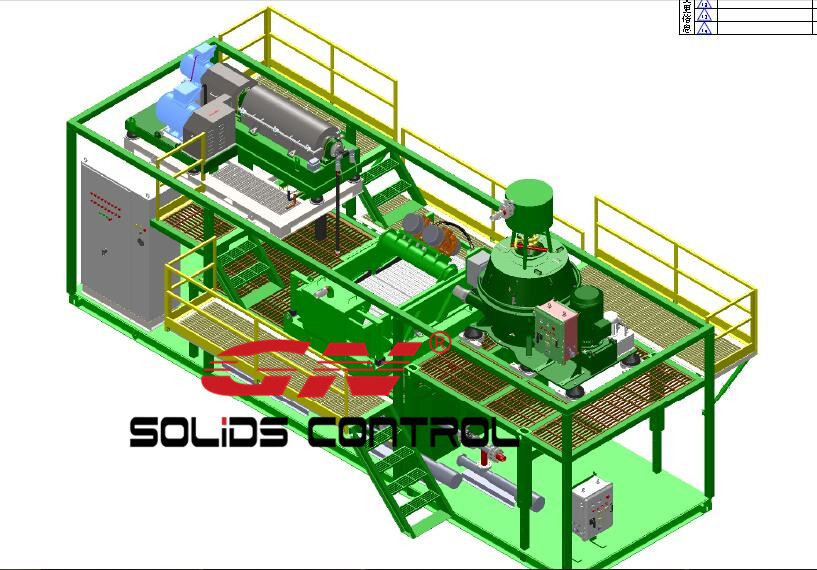

GN Solids Control is good at providing drilling waste treat systems, high density oil base cuttings, water base cuttings and synthesis base cuttings can be treated by using GN drilling waste treating equipment. Generally speaking, there are 3 mainly treating equipment includes shale shake, cuttings dryer and decanter centrifuge.

1. GN Shale Shaker

GN shale shake is the first phase treating equipment. Coarse solids can be separated out by using GN shale shaker. Usually, GN recommends using high G force shaker which can reach to 8.0 G. GN Hi-G shaker is mainly used to treat water base cuttings. There are 4 pcs of GN composite frame shaker screens fixed on the shaker deck, with the large vibration of USA Martin motors or Italy OLI motors, GN Hi-G shaker separate out most of the liquid inside the water base cuttings. Cuttings are transferred by screw conveyors and feed into GN shale shaker.

2. GN Cuttings Dryer

GN Cuttings Dryer has 3 size screen baskets: 250microns, 350 microns and 500 microns. Cuttings dryer is mainly used to treat oil base cuttings or synthesis base cuttings. With the rotating speed of almost 900 rpm, GN cuttings dryer separate the cuttings between the high rotating flights and screen basket. 4 sets of flushing outlets and 1 set air knife system are fixed on the cuttings dryer to keep it from blocking.

3. GN Decanter Centrifuge

Centrifuge is the second phase treating equipment, solids larger than 2~5 microns can be separated out. After treated by GN H-G shaker and GN Cuttings Dryer, slurry will be feed into decanter centrifuge by using screw pump or submersible pump.

Now GN Solids America LLC has these drill cuttings treatment system. GN shale shaker, GN decanter centrifuge and GN cuttings dryer is stocking in Houston warehouse. If you need any equipment, GN Solids America LLC can ship them from Houston immediately.

- Details

-

Published: 16 September 2017

GN Solids Control manufactures various feeding pumps which can be used to transfer high density slurry. Now GN feeding pumps include: centrifugal pump, submersible pump, screw pump etc. Pumps are wearable products, the pump shell and inside impeller need to be change after use for a long while.

GN centrifugal pumps are totally interchangeable with Mission Magnum pump.

Submersible pump is usually used to feed into decanter centrifuge, same as screw pump. Screw pump is also called positive displacement pump, it includes stator and rotator. Screw pump transfers the slurry without agitating the fluids too much.

This year, GN Solids Control also launched one new pump which is vacuum pump. GN Vacuum Pump is especially good at transfer high density slurry, such as drilling cuttings in a large height mud pit.

Every year, GN Solids Control manufactures various mud pumps. And this year, GN Solids Control receives many inquiries on centrifugal pumps, submersible pump, shear pump and vacuum pump. Here is one former inquiry we’d like to share with you:

I'm looking for your kindness to provide me with the quotation for SCREW PUMP. Please quote me as soon as possible.

Please refer the item below. If you need any further questions just feel highly appreciated to

let me know, I will response promptly.

NO PRODUCT NO. DESCRIPTION QTY UNIT

PUMP, 2 EA

Item Name (to purchase): SCREW PUMP

Application: INDUSTRIAL

Size Outlet: 1.1/2 IN

Size Inlet: 1.1/2 IN

NOTE: Your offer should be accompanied with;

1) Official Quotations

2) Warranty Period

3) Technical Specifications

4) Data Sheet & Catalog (Drawing)

5) Certificates belong to the offered items

6) Estimate Weight

7) FOB Port, Country of Origin

8) Freight Charges

9) Validity Offer at least: 60 days

GN manufactures various screw pumps, based on motor power and treating flow, GN recommends one certain screw pump to our customers. And GN Solids America LLC also has screw pumps in Houston warehouse.

- Details

-

Published: 10 September 2017

GN Solids Control is one of the most famous shaker screen manufacturers in North America. Now GN Solids America LLC provides replacement shaker screens like Mongoose, Venom/ King Cobra, VSM 300, FSI and Derrick as well as some other types. GN Solids America LLC has a Houston warehouse which can stock screens more than 6000 pcs. Various types of screens are stocking in Houston warehouse for fast delivery.

GN Solids Control has been working on manufacturing shaker screens for many years. Until now, GN shaker screens are using in more than 70 countries. GN Solids Control has done a lot of compare testament with the OEM screens, it turns out GN shaker screens especially those composite frame shaker screens are better with the OEM screens. While if you compare the price of GN shaker screens, you very be very highly impressed. GN Solids Control is always looking for providing the most cost effective shaker screens to global customers, besides shake screens, GN Solids Control also manufactures some other solids control and waste management equipment, such as shale shaker, de-sander, de-silter, mud cleaner, cuttings dryer, decanter centrifuge. GN Solids Control is also good at manufacturing turn-key solids control system, such as drilling waste management system, soil remediation system, dredging system etc.

GN Solids America LLC has provided thousands of shaker screens to North America shake shaker users. Now GN Solids Control manufactures 2 types of shaker screens, based on the screen frame material GN screens are divided into composite frame screens and metal frame screens. GN composite frame shaker screens are using mould to manufacture the screen frame outside of one metal frame screens. The metal frame are welded by using robot in order to keep the welding seam is a good consistence.

If you need any screens, feel free to connect with us. And we welcome everybody to compare GN screens with the other types of shaker screens.

- Details

-

Published: 02 September 2017