As a leading manufacturer on solids control equipment and waste management systems, GN Solids Control has been delivered its products to over 70 countries and regions. GN Solids America LLC is one branch company of GN Solids Control. With the fast development of GN Solids America LLC, now GN Solids has more and more inquires every month, we are willing to invite some partners to join us and built a win-win cooperation.

GN Solids Control is especially good at manufacturing all the solids and liquid separation equipment. In GN Houston warehouse, there are many shale shakers, desanders, desilters, mud cleaners and decanter centrifuges as well as cuttings dryers in stock. GN Solids Control products have been largely proved to working in various industries. GN Solids Control focus on oil and gas area, but more and more industries are using GN Solids Control equipment.

With these years development, GN Solids Control has made large progress:

1. GN Solids Control is Leading Manufacturer in China;

2. GN Solids Control is the first API certified manufacturer on solids control and waste management in China;

3. GN Solids America LLC is first Solids Control company that built in USA from China.

4. GN Solids Control has various certificates like ISO, HSE etc. Also certified by DNV CE, Russia TP & TC.

5. GN Solids Control has exported to over 74 countries or regions.

There are many glorious history stilling writing by GN employees. GN Solids Control is devoted to be the world top one solids control and waste management manufacturer. Now GN Solids Control is willing to invite some partners to join us and expand business in USA, Canada and Mexico. GN Solids Control will provide the most cost-effective equipment and the best after sales service. GN Solids Control is pretty open to discuss on various cooperation.

- Details

-

Published: 01 June 2017

Are you looking for the most cost- effective shake screens? Are you want to have some screens in s short time? Then you need to connect with GN Solids America LLC for shaker screens.

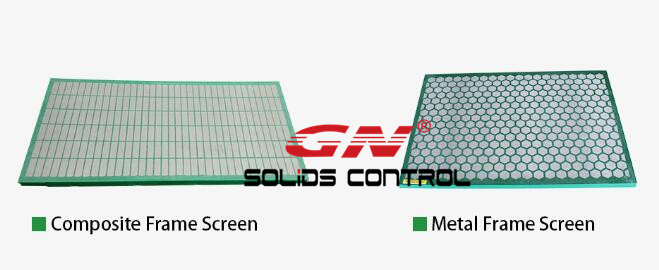

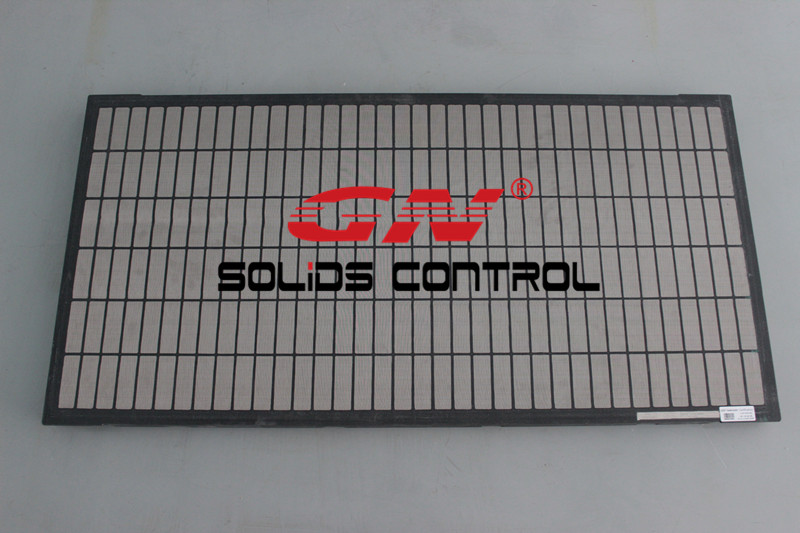

GN Solids Control is a leading manufacture on shaker screens, over 5000 pieces of screens are manufactured. Now GN Solids Control manufacture all the replacement screens which can be used one Mi-Swaco shaker , Derrick Shaker (500 and 2000), Fluid System shaker, NOV Brant Shaker etc. GN replacement screens are widely used in over 74 countries and regions, more and more shaker users are coming to GN to purchase shaker screens. And GN Solids Control also provides customized logo and API tag for various shaker manufacturers.

With the opening of GN Solids America LLC, more and more local customers from North America are getting to know GN shake screens. Now GN Solids Control has more than 3000 pieces shaker screens are stocking in Houston warehouse. Basically, GN Solids America LLC keeps replacement Mi-Swaco Shaker screens, replacement King Cobra/ Venom screens, replacement 285P (Nov screens), replacement FSI screens as well as replacement Derrick screens stocking in Houston.

Whenever customers have immediate demands, shaker screens can be packaged and delivered in a really short period. Shaker screens are wearable parts, you use them and you throw away. We have to admit that the manufacturing cost is pretty high in USA, while if we made in China, we can help customers save a lot. For the typical drilling rigs that uses 4 sets of Mi-Swaco shakers, screens need to be changed every 3~5 days, which is around 120 pcs shaker screens. If customers use GN replacement composite frame screens, customers can save at least 100 usd for each piece, which is 12,000 usd/ month and 144,000 usd/year. GN Solids Control has widely tested GN made composite screens, for the same drilling mud, GN screens are even performing better.

Please call 713-878-0880 for the most cost-effective shaker screens.

- Details

-

Published: 25 May 2017

GN Solids Control has been working on designing and manufacturing turn-key solids control and drilling slurry treatment solutions for many years. With more and more GN equipment and treating systems successfully used in customers’ work site, there’re more inquires on solids control treating systems.

Just several weeks before, GN Solids Control won a large order of 1000GPM solids control treating systems from one European drilling customer. There are many strict rules and regulations need to meet in order to win this tender, eventually, GN Solids Control left a pretty professional experience for customers.

Although there are still many technical details need to be further discussed, GN Solids Control is pretty confident to provide another satisfied cost-effective solids control system. Typical, GN Solids Control System includes the following part:

1. Shaker Tank

GN Shale shakers are usually used by 2 sets or 4 sets. Considering the maintenance and shaker screen changing, it’s better to have 2 backup shale shakers. Due to GN Solids Control are manufacturing the most cost-effective shaker screens, so from the long run, drilling companies will save a lot on shaker screens investment as they are wearable parts and need to change frequently. GN Mud Cleaners (include GN desander cyclones and GN desilter cyclones) are also used. After treating by GN shaker tank, solids larger than 25 microns can be separated out.

2. Centrifuge Tank

Decanter centrifuges are all commonly used. Generally speaking, one middle rotating speed centrifuge and one high rotating speed centrifuge will be used. The first one is used to separated out most of the solids. While the second centrifuge also called polishing centrifuge is used to eliminate those much finer solids.

3. Mud Mixing Tank

After treated by above equipment, GN mud mixing tanks are used to prepare new drilling mud. A GN Jet Mud Mixer is common seen to add drilling additives and make new drilling mud.

4. Mud Storage Tank

Mud storage tank will stock those new drilling mud and keep them agitating. New drilling mud can be reused.

- Details

-

Published: 18 May 2017

As a branch company of GN Solids Control, GN Solids America LLC has been in Houston, TX for almost 4 years. Although GN Solids America LLC is still a baby company, with the great help from GN Solids Control, GN Solids America is getting known by more and more solids control and waste management customers.

Now GN Solids Control manufactures 9 inch centrifuge, 14inch centrifuge, 18inch centrifuge, 22inch centrifuge and 30 inch centrifuge. Different models can be used in different areas due to the treating volume and G force differences.

Such as the barite recovery, most of the solutions we provided to our customers are dual centrifuge systems, sometimes 3 centrifuges might needed. Here is one typical (probably the most cost effective) barite recovery solution:

1. One 18inch middle rotating speed centrifuge GNLW452 (815 G force @1800 rpm), this is used to recovery barite or separate out High gravity solids.

2. One 14inch high rotating speed centrifuge GNLW363 (2062 G force @3200RPM), this is for separating out low gravity finer solids.

Frankly speaking, GN 30inch centrifuges are mainly used on TBM drilling slurry separation or some other industry slurry treatment areas. Treating capacity is 528GPM (mud with 20% solids). It's not common to use it in the oil and gas area as they don’t have such large drilling rigs.

GN Solids Control has provided centrifuges to more than 60 countries, with the successful usage by many large customers such as Shell, Baker Hughes, Bariod etc. If you are looking for the small centrifuge like 14inch, 18inch and 22inch, we do can provide you with hundreds of successful projects. According to our former experience, when the mud weight below 11ppg almost all the customers are not collecting them.

Now GN Houston warehouse has many centrifuges in stock, welcome to check our Houston warehouse for your decanter centrifuge needs.

- Details

-

Published: 11 May 2017

The world largest oil and gas show, OTC is just around the corner, GN Solids Control and GN Solids America LLC will participated in this great show and have two separate booths.

GN Solids Control has been attending the OTC (offshore technology conference) since 2011, now it’s become a tradition for GN Solids Control to participate in the OTC show every year. As the most influential show for oil & gas industries, OTC has over thousands exhibitors attended every time. There are three exhibition halls: Center, Arena and Stadium in NRG park, Houston, TX.

As usual, GN Solids Control will have a large booth in Center and in a standard booth in Arena. GN Solids Control is only devoted to designing and manufacturing various separation equipment and systems. GN Solids Control is getting to know by most of the oil and gas companies especially by those solids control and waste management companies and professionals. GN Solids Control only provides the most cost-effective equipment to global customers. Many large customers are using GN Solids Control equipment to do the solids and liquid separation work and they actually perform excellently well. As a world equipment provider, GN Solids Control products now have been widely used in more than sixty countries.

This year, GN Solids Control will exhibit the upgraded shale shaker. GN Solids Control engineers are very professional to provide the best solutions, every year GN Solids engineers are sent to global worksites and collect valuable working performance data. Based on that, GN engineers will modify or upgrade all GN Solids Control equipment accordingly. GN Solids Control engineers are always trying to offer the most cost –effective separating solutions.

Various shake screens will be also exhibited in the OTC show. GN Solids Control now manufacture over 5000 pieces shaker screens, with the opening of the No.2 factory, GN Solids Control now can manufacture all flat panel shaker screens with composite material which means the metal frame screens are also coated by high quality composite material.

- Details

-

Published: 13 April 2017