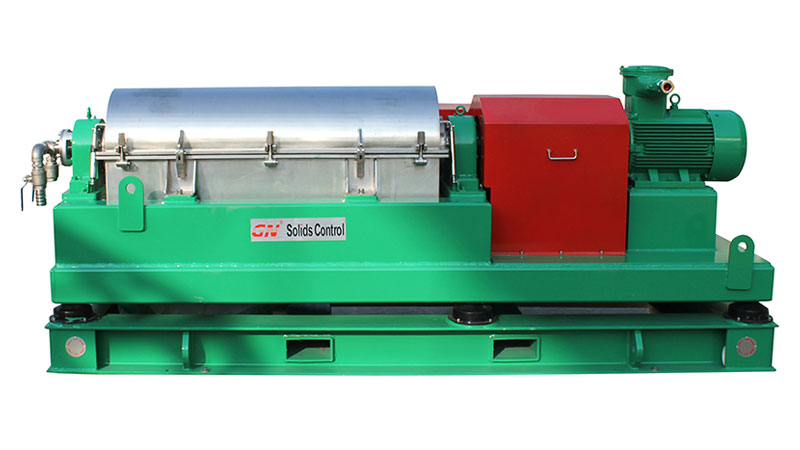

GN Solids Control manufactures different sizes of decanter centrifuges, among which the 9 inch bowl centrifuge is the most popular one. GN Solids Control 9 inch decanter centrifuge is mainly used in small flow rate mud treating, such as diamond drilling slurry treating, core drilling mud treating, animal waste treating as well as any lab scale slurry treating.

In the past several years, GN Solids Control has provided almost 100 sets 9 inch bowl decanter centrifuges in Canada, most of them are using in diamond drilling slurry treating.

This week, GN Solids Control shipped another 8 sets 9 inch bowl decanter centrifuges to Canada. As we all know, Canada is a very highly modernized country, when we provide decanter centrifuges to them, they usually use GN centrifuge rotating assembly and fix motors & control box by themselves.

GN 9 inch centrifuge rotating assembly mainly includes the following components: rotating bowl, screw propeller and collecting box.

1.GN 9 inch centrifuge rotating bowl is made by centrifugal casting, solids discharge port is protected by tungsten inserts.

2.Screw propeller is inside the rotating bowl, it rotates at same direction but at lower speed, solids can be pushed from the feeding end to the rotating bowl discharge end.

GN Solids Control test run all the centrifuges 3 times dynamic balance checking for the rotating bowl, screw propeller and assemblies.

3.Collecting Box

Collecting box is made of stainless steel. All the discharge solids meet the inside collecting box and fall off to the bottom catch tank.

With more and more customers are using GN decanter centrifuge, GN Solids Control is able to provide the most cost-effective solutions to global customers. GN Solids Control also manufactures hydraulic driven type decanter centrifuges, hydraulic driven parts are provided by Sweden manufacturers.

Now GN Solids Control has some sets decanter centrifuges stocking in Houston for fast delivery, welcome to connect with us if you need any centrifuges.

- Details

-

Published: 16 January 2020

GN Solids Control has been manufacturing shale shakers for many years, now GN Solids Control is able to provide more than 300 sets shale shakers every year.

Just last week, GN Solids Control finished manufacturing of another 6 sets shale shakers, which will be shipped to a Russian customer.

GN Solids Control manufactures different types of shale shakers, includes single layer shaker: 2 panels, 3 panels and 4 panels and double layers shaker: 6 panels. When shale shaker fixed with different sizes of cyclones, it will become de-sander if use 10 inch cyclones and de-sitler if use 4 inch cyclones.

These 6 sets shakers GN Solids Control provided is GN 4 panels shale shaker, which is able to treat 500 GPM. When use different API nos. Shaker screens, this shaker will have various treating flow rate.

GN Solids Control shake shaker is only use 2 vibrators: one brand is USA Martin and the other brand is Italy OLI. Both vibrators are have very good quality and provide satisfying after sales service. All GN shale shakers are fully tested before leave factory.

As one of the very important market for GN Solids Control, GN has selling a lot of solids control equipment includes shale shakers, desanders, desilters, mud cleaners and decanter centrifuges to Russia. Word of mouth reputation has helped GN Solids Control to receive more orders from customers.

Besides shale shakers, GN Solids Control is also able to provide shaker screens to fit GN own shakers as well as the other popular used shale shakers. GN Solids Control now manufacture more than 5000 pieces of shaker screens every month, which is able to meet most of the customer’s demands. And GN Solids Control is able to double or triple this amount if we got more orders. Also, GN Solids America LLC is stocking thousands of shaker screens for fast delivery.

- Details

-

Published: 08 January 2020

As a branch company of GN Solids Control, GN Solids America LLC has provided hundreds sets of shale shakers and mud cleaners in North America this year.

This week, one USA customer came to pick up another set mud cleaner. They have been using more than 5 sets GN shale shakers for a long while. When they upgrading their current systems, they decided to use GN mud cleaner without hesitation.

GN Solids Control manufactures 250 sets to 350 sets shale shakers every year. Until now, GN Solids Control has provided solids control and drilling waste management systems to 70+ countries and regions, more and more customers from other countries prefer to use GN Solids Control equipment and systems.

GN Solids Control is the first API certified solids control and waste management manufacturer in China who has 3 manufacturing plants close to Beijing. With one USA branch company GN Solids America LLC and one Russia branch company GN Solids Russia.

Usually, GN Solids America LLC keeps 6 sets shale shakers, 2 sets mud cleaners and 2 sets decanter centrifuges in stock for fast delivery. GN Solids America LLC also keep the spare parts and wearble parts in stock in case they need them urgently.

With these 5 years’ fast development, GN Solids America LLC is widely known and recognized by oil and gas professionals. GN Solids made equipment is famous for the most cost-effective character, all GN made equipment is equivalent to USA manufactures but the price is way lower.

Word of mouth helps GN Solids America LLC grows faster and faster. Many customers are only using GN made solids control and waste management systems as they have witnessed GN equipment always do the tough work successfully.

If you need any solids control and drilling waste management equipment, please feel free to connect with GN Solids America LLC for more details. We are always here to help.

- Details

-

Published: 21 December 2019

After days of hard work, GN Solids Control has finished the helicopter lifted mud tank systems for one Australia. Last week they rented two air-crafts to transport this whole mud system to Papua New Guinea.

This is another compact helicopter lifting mud system we provided in this year. In order to move easily, GN Solid designed and manufactured this system into compact small systems.

Here are the mainly treating modules in this compact mud systems:

1.GN Gas Separator Unit

GN mud gas separator is put on a skid for easy moving. A large supporting skid is used to hold the gas separator when lay down. GN mud gas separator is used to eliminate large bubbles in the drilling mud.

2.GN Shaker Unit

There are several shale shakers on the shaker module, a box feeding is used to distribute drilling mud to those multiple shake shakers. Larger particles more than 100 microns can be separated out by GN shale shaker.

3.GN Desander Unit

After treated by GN shaker, drilling mud is feed by centrifugal pump to GN desander. A helicopter lifting frame is used to transport the shaker unit and desander unit.

4.GN Mud Mixing Unit

A mud mixing hopper is used to add drilling chemicals and mix drilling mud. The hopper is using a venturi hopper to mix the drilling mud.

All the above treating equipment can be divided in to some smaller treating units. Every individual system can be lifted by a helicopter when arrived at customer’s work site. As all the mud tanks systems are connected with drilling pipes etc, after arrived at work site they just need to connect with the pipe lines between those mud tanks.

GN Solids Control is especially good at providing turnkey solids and liquid separation systems. Feel free to connect with us if you need any mud separating systems.

- Details

-

Published: 14 December 2019

As one of the largest environmental shows in the world, the 2019 Italy Ecomondo show had thousands of professional visitors. It was held in Rimini Expo Center in Italy from Nov. 5th to 8th.

GN Separation and Conveying is the sister company of GN Solids Control, it participated in many different environmental shows this year. Months ago, one branch comapany GN Solids America also participated in WEFTEC in Chicago, which is another largest waster water treating show in North America.

Every time when GN Separation and Conveying goes out to participate different shows, GN prefers to bring some real equipment instead of only exhibit some fancy pictures. We always hold the principle that ‘Seeing is Believing’.

In the 2019 Italy Ecomondo, GN Separation and Conveying exhibited one decanter centrifuge and one vacuum pump.

1.GN Decanter Centrifuge GNLW224E

GN Separation and Conveying manufacturing different sizes of decanter centrifuges, includes 9 inch, 14inch, 18inch, 22inch and 30 inch bowl centrifuges.

GN made 4 series centrifuges are especially designed for thickening, detwatering and cleaning. In order to meet the treating demands for different slurry or materials, GN Separation and Conveying made centrifuges have different screw propeller angles, cone and strait part ratio is also varies, also we provide single edge and double edge propellers.

Centrifugal rotating bowl is made of centrifugal casting by stainless steel. Inside screw propeller is protected by tungsten carbide tiles. All the solids discharge ports are also protected by tungsten inserts.

2.GN Vacuum Pump GNSP-10B

GN Vacuum Pump is one of the most cost effective transfer pumps. It helps to transfer high content solids with large viscosity and density.

GN builds 3 different models: 40B, 20B and 10B. Transfer capacity is 40 m3/h, 20 m3/h and 10 m3/h.

During working a air compressor should be used to provide power. Different size pumps need different air pressure.

- Details

-

Published: 07 December 2019