After 13 years development GN has been the leader of solids control equipment. We had built three plant with more than 800000 square meters to manufacture different solids control and waste treatment equipment .Most GN equipment is used for drilling mud treatment to remove its solids and clarify the mud again for reuse . Actually GN equipment not only an be used for the oil gas industry ,but also good performance at some environment projects. Such as the waste water treatment. Last week we delivered vertical cutting dryer and screw conveyor to our customer .

The vertical cutting dryer is not used to treat the drilling cutting , which is used to dryer the solids phase that separated from shale shaker in the waste water treatment project. As usual , the solids discharged from shale shaker is very wet, it is inconvenient to transport, so we need to dryer it .GN vertical cutting dryer is big capacity machine with 50 tons /hour. And it is continuous work .After treatment the liquid content is only 8%-20% according to the different situation .It is a stable equipment ,the inside screen is processed with the special technology and anti -wear material. That can ensure the long lifetime . from the picture you can see that it install in a container ,that is because this project is a very cold area and it is also convenient for transport.

Except the cutting dryer , we also equipped the screw conveyor to feed material to cutting dryer ,solids will directly convey from shale shaker. This will help to improve the efficiency and reduce the cost of labor . The screw conveyor can increase the length according to the actual requirement , you just need to add the module section ,each section is 12 feet. Big capacity and stable.

GN has full experience in the solids-liquid separation ,not only in the oil gas industry ,but also environment project , if your project have demanded in these equipment , please contact us.

- Details

-

Published: 02 August 2020

GN is a leader of solids control equipment in China .We have focused on providing the equipment and service to energy company for more than 13 years history. Except GN HQ in China , we built two branch company in Russia and USA, the two branch company can quickly provide the after sale service for local client. And in USA branch, we built our warehouse in Houston for rapidly response to customer purchase.Last week we delivered the vertical cutting dryer to Russia.

GN vertical cutting dryer is completely independent research and development ,this cutting dryer after several upgrade,which can win the mote difficult working situation and get the good feedback from customer. Not only the cutting dryer ,but also all GN equipment comply with API quality management, especially the shaker screens passed the strictly test by the third part and got the API RP13C report .

GN vertical cutting have fixed speed and VFD two model. For this customer ,we delivered the fixed speed model. The rotating speed is not adjustable. As we all know the Russia is very cold ,this is a challenge for every equipment and also operator .We put the cutting dryer into the container house to keep warm and make sure the best work performance.This vertical cutting dryer most times used for oil base mud .The drilling mud after shale shaker treatment ,the discharged solids steel is still contain large liquid. These solids can directly feed into cutting dryer, after treatment the OOC will less than 5%, which is very dry and convenient to transport and reduce the pollution .Most important is that the mud discharged by cutting can be used again for drilling .The capacity is 30-50tons based on the actual situation .High efficient,stable,environment friendly ,If you have demand in these equipment ,we will be pleased to provide the technical support and share our experience.

- Details

-

Published: 26 July 2020

After 13 years development ,GN is always consistent to provide the separating solutions for global customer .At the begin of company fund, we devote ourselves to reduce the cost for the solids-control industry by providing the high effective equipment . We do invest large capital to develop the new technology and new equipment based on the customers’ requirement. As we all know ,GN have the series equipment for different size particle separation ,shale shaker ,mud cleaner ,Decanter centrifuge ,degasser. Sometimes when the particle size smaller than 2 um with the low solids content , even the decanter centrifuge can not remove the solids from the liquid, then we need to add flocculant to mix with the material .This chemical will combine the tiny particle into big size ,and then our centrifuge can separate the solids with high efficient.

Last week we delivered 1 set chemical dosing unit to Africa customer .This unit be used for a dewatering project .After the testing in lab,our client find the adapt chemical and dosage for his slurry ,so in the actual operate ,which will need chemical dosing unit to control the dosage. This unit is a automatic machine , operator just need to set up the dosage in the control box, then will accurately feed medicine.

The unit main include medicine hopper, tank,flow control pump,water tank , control box . And for this special using situation with high temperature in Africa , our engineer equipped the air condition to ensure the unit best work performance. The flow measuring pump is diaphram pump equipment the control to adjust the flow. As we can see from the picture ,there are agitator on the tank ,this main used to mix chemical and water,after mixing the liquid will be pump into dewatering system.

This unit not only used for flocculant feeding ,but also can be used on some other chemical ,such as demulsifier . If you have demanded in this equipment , welcome to contact us , we will be pleased to share our experience and provide the technical support.

- Details

-

Published: 17 July 2020

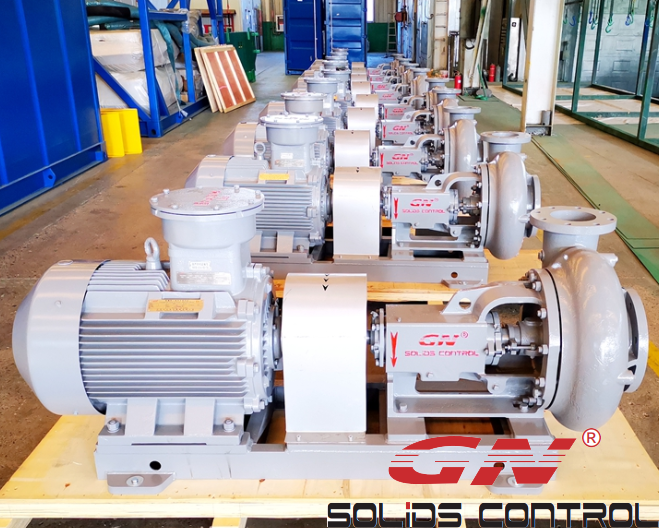

After 13 years development in the solids control industry ,GN has the built the rounded system to manufacture solids control and waste treatment equipment. As we all know these equipment is used to separate out solids from the sludge ,all these system need centrifuge pump to transfer material .Centrifuge pump is widely application in different industrious.

Centrifuge pump is one kind pump that take advantage of centrifuge force to transfer the material. It main involve the pump head and electrical motor , which is very simple structure. As usual the pump capacity can reach 320material /hour with 75kw motor , so it is a good choice for some project that require big capacity . This pump can not suck ,so the inlet need to submerge into the liquid , and pump lift between 20-35meters when pump clean water .The density of material is more bigger ,the capacity will be more smaller.

There several big and famous pump manufacturer in the world .GN centrifuge pump parts are 100% interchangeable with pump from these famous brand , quality is stable and get the good feedback from customer .The interchangeable parts means that it is easy for client to find the part supplier in their local ,which is convenient for the after sales. In the drilling mud system , the centrifuge pump can be used to feed slurry to shakers ,or combine with mud hopper to be a jet mud mixer .When feed slurry to the mud cleaner ,the pressure usually require 0.2-0.4 MPA , the small pressure will lead to bad separation performance ,so need to pay attention to the pump pressure.

GN can provide different capacity pump and parts ,the electrical motor selected the famous brand of China , table quality and good after sale service ,if you have demand in pump , please feel free to contact us .

- Details

-

Published: 12 July 2020

GN Solids Control is a famous with his solids control equipment in the petroleum market. With the 13 years development , GN equipment not only only used in the drilling mud ,but also widely used in the other industry for the solids liquid separation. As a global company ,we had built our branch in Russia and USA to serve different territory customer. We committed to provide the environment friendly equipment and solution to the different industries. Sustainable development is always our guideline to developed the new technology. Last year we are honored to took part in one waste water treatment project ,and provide 4 sets Decanter centrifuge for this waste water plan.

In the waste water treatment ,decanter centrifuge is the last step of chemical separation for the big size partical. Under the high rotated speed ,which will generated 2500-3000 G force , the small size solids will be separated with water and generated layering inside the centrifuge bowl , and then the below solids will be discharged. As usual the water plant require the big capacity centrifuge. GNSLW764 Decanter centrifuge is our biggest capacity model with 120mud /hour .The centrifuge bowl diameter is 760mm and the length is 4times of diameter ,Which is automatic and continuous. Compare with other equipment only need less worker to operate and the separation performance is more better.

Each GN decanter centrifuge must go through 3 balance testing . one is separately testing for bowl , and the assemble together for centrifugal bowl , the last is whole set machine test. We have strictly control to the material and part supplier , such as the bowl material used SS2304, the strength is more higher than other steel material .The control box choose the SMENSE or ABB, which quality is stable ,and the most important is that client will be easy to find the electrical part for replacement from these bran agent in their local .If you also have the demanded in centrifuge , please feel free to contact us.

- Details

-

Published: 05 July 2020