Last week we delivered one unit GNLW363 decanter centrifuge to our Bolivia client. This decanter centrifuge was used for the drilling mud treatment. It is the first time for this client to use our equipment. Client had known GN decanter centrifuge from other user, actually GN decanter centrifuge is vary popular in Latin America, and we had exported more than 50 units decanter and several sets solids control system. Competitive price with stable quality help us to gain many clients from Trinidad, Mexico , Peru and also Brazil. To provide quick service, we built out America branch in Houston. Both north and south America client are convenient to contact us for immediately response.

GNLS363-VFD is the second small decanter of GN.Which most used for some client that have a low requirement to the treating effect, such as drilling mud. The length of centrifuge bowl is 1271mm, it is 3 times of diameter, it is not enough long for some material treating with high requirement to the discharged liquid. However, 363 decanter is the best option for drilling mud treatment. If you want more better separation effect, we can provide 364 decanter with 1512mm centrifuge bowl.

363 decanter centrifuge equipped one 37kw main motor and 11 kw back motor, the total power is 48kw. But in the actual application, the power consumption is around 32kw. VFD control is different with fixed speed drive, the rotating speed is adjustable. The max speed can reach 3200RPM and generate 3063 G separation force. The max treating capacity is round 45m3/hour. The higher solids content material will reduce treating capacity, and we usually suggest the best solids content is 10% when feed material to decanter. If the solids content is too high, a shale shaker for pretreatment is necessary to reduce solids content.

GN decanter centrifuge is our featured equipment, and has several series with different treating capacity, if you have demand on solids-liquid separation, welcome to contact us, we will be pleased to share our experience.

- Details

-

Published: 28 April 2021

Decanter centrifuge is one kind equipment that utilize the rotation to generate the separation force. Under the separation force, the different density material will bear various force, and reach the solids-liquid separation. The principle is similar with the drying of laundry. GN Solids control has focused on the solids-liquid separation industry for more than 1 years. We provide solids control equipment to oil gas industry for the drilling mud treatment. Our decanter centrifuge get the good reputation from market due to the reliable quality and good price, and the equipment was used in different industries.

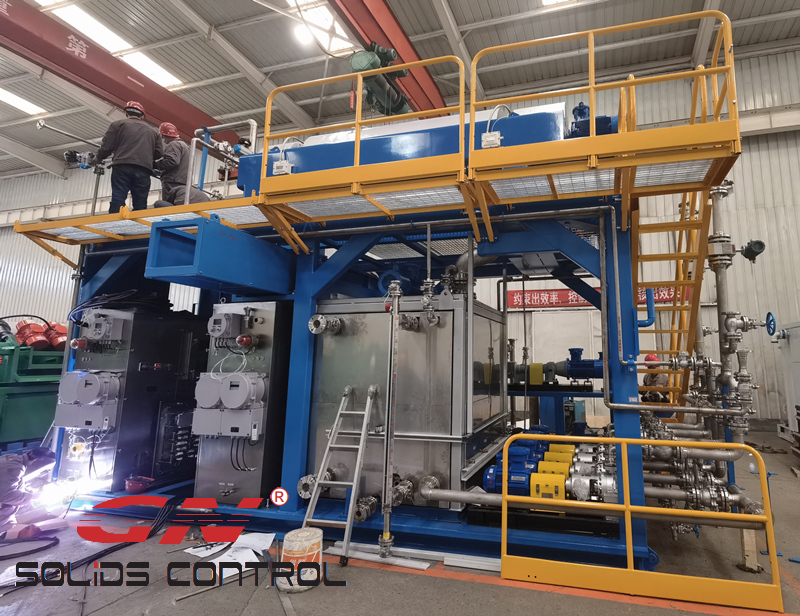

Last week we delivery one separation system to our client for the chemical separation. Little different with the oil gas industry, chemical separation required more higher G force to extract the tiny chemical particle. And also need to reach their requirement to the purity, which means the water content of discharged will be as lower as better. In the chemical separation system, which main include the GN554 decanter centrifuge, flocculant dosing unit and several pumps. Our customer will feed some kind flocculant to combine the tiny particle into bigger one, it will be helpful to centrifuge to remove out the solids as much as possible.

GN553 decanter centrifuge have more longer centrifuge bowl, which means the material will stay longer time inside decanter and get more separation time to reach the better separation. The half bitch angle is specially designed to make the discharged solids dryer and liquid clarify 500 mm diameter of centrifuge make it possible that generate 3000 G force under 2300 RPM. And the rotation speed is adjustable through GN VFD control panel.

From the picture you can see, this system has complex pipeline system, and all design was made by GN. We have an experienced technical team, and good at providing the customized solution for customer. If you also have solids-liquid separation project, welcome to contact us, we will be pleased to support.

- Details

-

Published: 21 April 2021

Core drilling use the small rig machine to drill and get the mineral samples, which is very popular in the mining exploration and especially in north American. In core drilling, most drilling job are in wild, and they are frequently transfer in different job site. Mini system is necessary for convenient transport. One other issue is the water, rig need water, we must have equipment to recycle the water and reuse it to solve the water issue in wild.

GN SRU (solids remove unit) was specially developed for the core drilling industry. It is a mini system, easily transport and satisfied the treating capacity of core drilling. It main include the GNZS752 shaker shaker, GNLW223 decanter centrifuge, mud tank, and also several pumps. This mini system treating capacity can reach 6 m3/hour with 2 separation equipment, and also equipment mud jet mixer to mix the drilling mud and store them. When drilling, the drilling mud will feed into GNZS752 shale shaker, it will remove out the big particle size bigger than 60 um. And then the discharged will feed into decanter centrifuge. As we all know, decanter centrifuge is one kind separated machine utilize the separation force generated through high rotation. Its G force can reach 3000 G, the different density material will be separated because they bear the different G force. Decanter centrifuge can separate out the solids between 2-5um. The discharged water can be directly reused in drilling system. The equipped 6m3 mud tank, which can be used to store the drilling mud beforehand, clean water or as a buffer tank.

This mini SRU is not only be used in mineral industry, but also some small solids control project. We had exported several sets to Canada, and also have agent in Canada to provide quickly service. If your project has demanded on these our solids control equipment, welcome to contact us, we will be pleased to share our experience and give the technical support.

- Details

-

Published: 14 April 2021

HDD is short of horizontal direction drilling, it is one kind rig machine that can directly drilling underground and will not break the ground surface. That is widely application on municipal project, such as the underground electrical wire system ,city drainage system. According to different project situation ,there may will use the drilling mud to cool rig and carry out the drill cutting from the tunnel. Compare with oil well drilling mud, this mud is easily to treatment.

Last week, we delivered one set HDD mud recycling system to out client. In this system, it include one 1000gpm/hour mud treating unit, jet mud mixer and mud tank. The mud treating unit is the main product to separate the drilling mud ,the unit has two 10 inch hydrocyclone mounted on GNZS706 shale shaker. Actually this unit can be individually used as mud treating system. GNZS706 is two layers shale shaker, pump feed the slurry in to the bottom layer shaker screen for first stage treatment, it can remove out the big size particle. The liquid will drop to the bottom tank through the shaker. The other centrifuge pump will suck the liquid from bottom tank into the hydrocyclone. In the hydrocyclone treatment ,the clean liquid will be discharged from big end to other tank for recycle. The separated solids will discharged through small end and drop on the up layer screen for further separation. Solids be move out and liquid go down the bottom tank. The drilling mud after the whole program separation, it will clear enough for reuse.

We also equipped one mud jet mixer in this system. The operator can dump the mud material into the hopper, through the venturi structure, the mud material will be sucked and mixed with water, and then pump into the mud tank.

Mud recycling not only be used in trencheless project, but also in tunnel boring, piling project etc. GN can provide the whole set solution according to client requirement. We will be pleased to share our experience if you have demanded on these separation equipment.

- Details

-

Published: 07 April 2021

GN Solids America was funded in 2013, as branch of GN Solids Control, it main provide service to north and south America market for quick response. Not only a office , we also built warehouse in Houston to reduce the shipping time. GN main produce separation and conveying equipment for different industries, especially in the drilling, our equipment get good reputation with stable quality. Not only separation equipment, GN centrifuge pump,screw pump ,submersible pump these equipment as corollary equipment of separation system, they are also popular in the market, especially the vacuum pump.

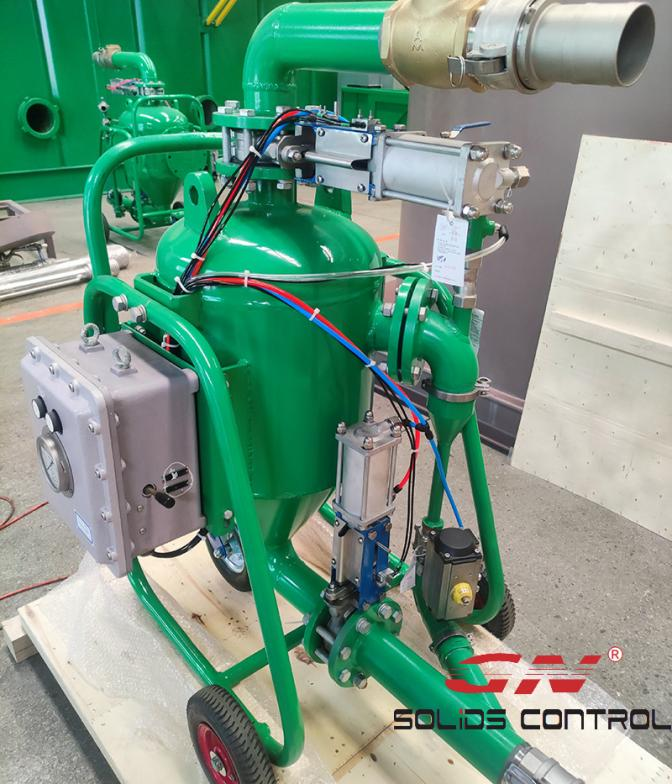

Last week, we delivered several sets vacuum pump to Houston warehouse. It is different with the normal pump ,it used to transfer the material with high solids content or solids particle that smaller than 50mm, such as the drill cutting, waste water from mill, cement etc. Vacuum pump is driven by air. The transfer capacity can reach 10m3-40m3 depend on the material density and viscosity. Pump empty the air and generate suction force , the material will be suck in to pump body. Then the air compressor will convey high pressure to the pump and push the material to discharged port. The pump max suction distance can reach 50 meters, and max discharge distance can reach 500-1000 meters.It is long suction and discharge distance, but the pump suck depth is less than 12 meters in vertical. This limit some client to use it transfer sludge from deep pit.

As we know, only 3 companies in the world can manufacture this kind pump. And GN Solids America LLC is only vendor to provide this pump. Even so,GN price is very reasonable and competitive compared with some other pump supplier. With the widely application , GN vacuum pump are known by more and more people , we improved our inventory to make sure the quick delivery. If your project have demanded on this pump, please contact us.

- Details

-

Published: 31 March 2021