GN Solids Control has been funded for more than 14 years. From the date of establishment, we are focused on the solid control industry and serve the drilling company and oil gas company , and help them solve the drilling mud treatment problem. In oil well drilling, the mud is very import middle material to cool the rig and carry out the drill cutting from well. It almost use the solids control system to finish this treatment.

As we all know, the mud system has several different kind equipment and mud tank. Which need many pump to transfer the the slurry from different tank. Centrifuge pump is the most common be used for in solids control system. At beginning, GN design the system ,and purchase the pump from other supplier for our solids control system. But the quality is not stable. Then we decider to make our own brand centrifuge pump with stable quality.

GN decanter centrifuge is one kind equipment with simple structure and stable quality. The pump connected with a electrical motor, through the motor drive the impeller to reach the slurry transfer. It can transfer the slurry with high solids content, but we need to note high solids content material will speed up the pump wear, especially the impeller. Centrifuge pump has not the ability that suck the material , the liquid level need to higher than suction port.

In the centrifuge pump , which has many spare part, so it will need supplier can provide the part quickly when client maintain the pump. Considered this point, GN decanter centrifuge spare parts are 100% interchangeable with Mission Magnum. Client can get the parts from GN ,or directly use Mission part. That will be convenient for client to repair the pump.

GN centrifuge pump have several kind model from 11kw-75kw with flow rate 45m3/hour to 320 m3/hour. Client can choose according to the requirement. For America user, you can directly purchase from our Houston warehouse and also the after sale service. GN centrifuge pump is stable with competitive price. If you want to know info, welcome to contact GN Solids Control.

- Details

-

Published: 24 March 2021

Hydrovac excavation is one popular in developed country. It utilized the high pressure water flush the ground and finish the excavation. Compared with normal excavation method, it is high effective, will not damage the pipeline under ground, and also the sludge will be sucked by hydro vac truck, so there is no pollution. However, the collected sludge always the big problem for treatment. GN dewatering system is specially used to treat this kind sludge. Last week ,we delivered 1 set dewatering system to our New Zealand client.

In this dewatering system, this will include mud catch hopper, coarse shaker ,mud cleaner and decanter centrifuge. As we know ,the sludge will be collected by hydrovac truck, the catch hopper make it easy that truck can directly dump the sludge into the hopper. It will improve the efficiency and prevent the splash. The catch hopper will feed the sludge into coarse shaker. The sludge always include some big solids ,such as gravel ,plastic, stone etc. Coarse shaker can separate out these big size solids, and finished the first stage of classify.

The liquid after coarse shaker will be feed into mud cleaner , through the the hydrocyclone , the solids that bigger than 40 micron will be remove out . In this step, the solids content will down to 20%. This is very import for the next separation stage by decanter centrifuge. Because the high solids content slurry will affect the working performance of decanter centrifuge.

In the final stage, the decanter centrifuge will separate out the solids smaller than 20um .Under the max 3000 G separation force, 95% solids will be removed. The discharged water is clean enough to reuse for the hydrovac excavation. This will save much cost of water. Meanwhile, the recycled solids can be used for building material according to the size. GN dewatering system is environment friendly, it get the good feedback from client to solve the sludge treatment problem , and recycle the water and building material to save resource.

We had built 11 sets dewatering system in North America, if you have demand ,welcome to contact us for more information.

- Details

-

Published: 17 March 2021

Last week we shared part instruction how to disassamble the inlet pipe of decanter centrifuge, we will continue to share the following steps. Hope that will be helpful when you maintain your equipment.

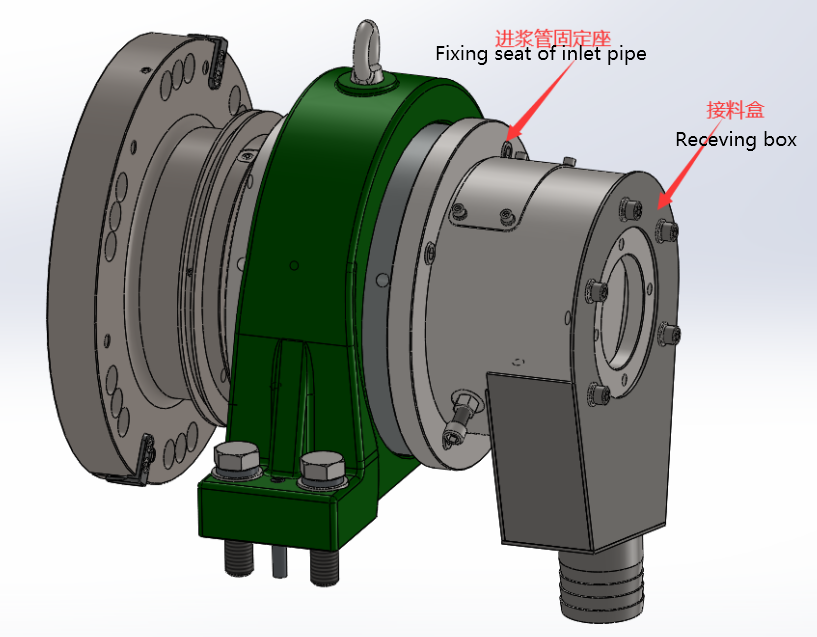

5. For thesmall end cover that has been removed , remove the receiving box and the fixing seat of the slurry inlet pipe .

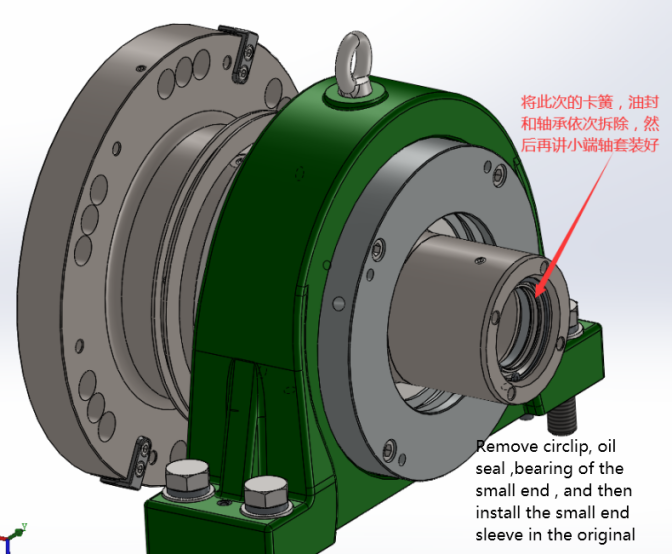

6. Remove the sleeve of small end, take out the circlip, oil seal and bearing of the small end , and then install the small end sleeve in the original position.

7. Check the big end side of small end cover, and ensure bearing lubrication is good, no foreign matter, then replenish the grease.Install the small end cover according to the marked line.

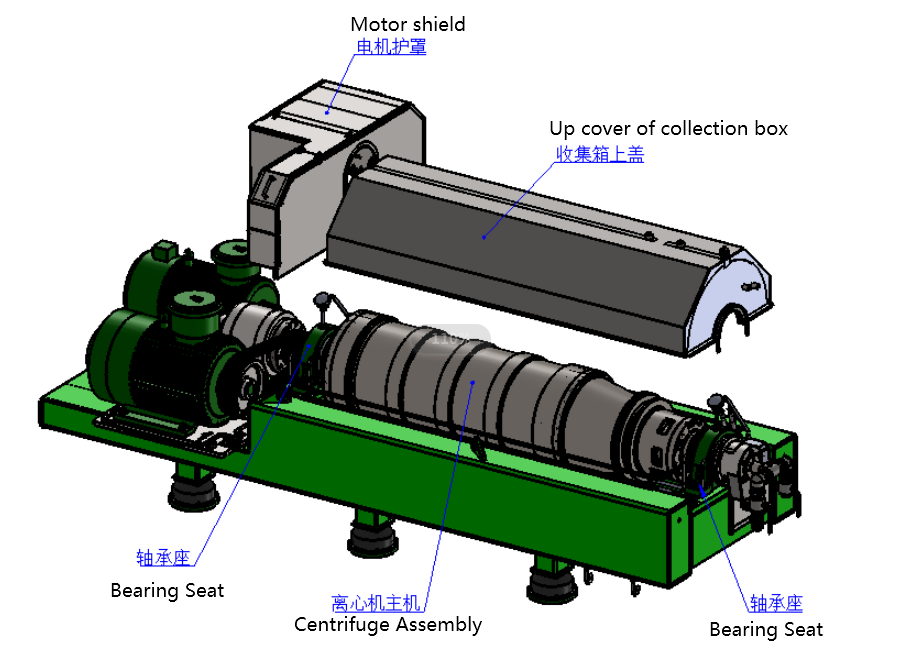

8. Hoist the centrifuge assembly to the centrifuge base,put on the bolts, turn the centrifuge bowl by hand to make sure no scratching and abnormal noise. Install the positioning pins and tighten the bolts, turn the drum again to confirm that there is no abnormal.

9. Install the inlet pipe fixing seat and the receiving box in their original positions, and then the belts of main motor and auxiliary motor .

10. Install the upper cover of the collection box, tighten the bolts, turn on the equipment to see if there is any abnormality. After confirming everything is normal, install the inlet pipe, turn on the equipment again to confirm that there is no abnormal sound, scratch, etc., Install the motor shield, and start the equipment. Observe the work status, and check the bearing temperature . Commissioning with 4 hours idling to make sure no abnormalities

- Details

-

Published: 10 March 2021

Inlet pipe as a spare part of decanter centrifuge, it need to replace sometime. The following is one case of inlet pipe replacement.

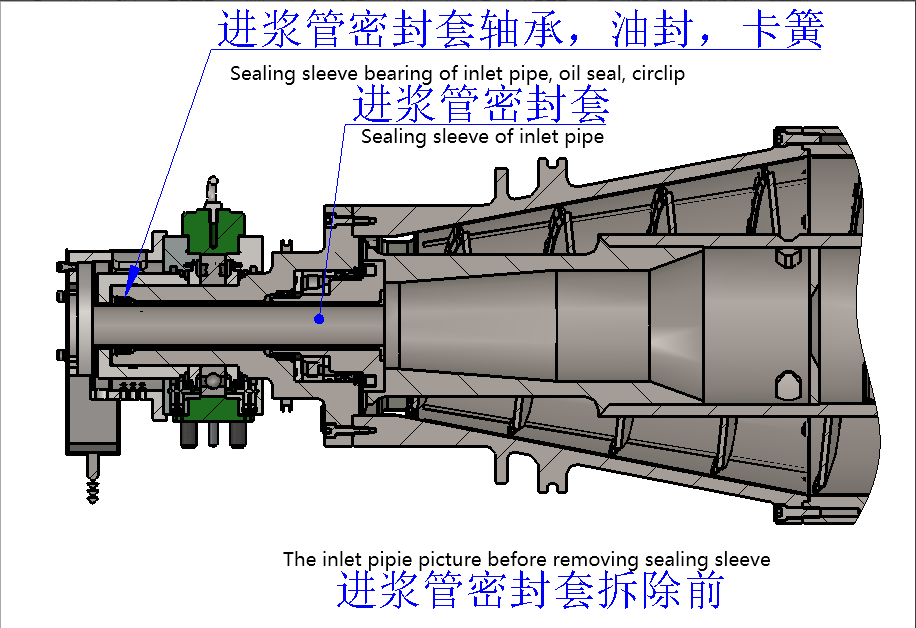

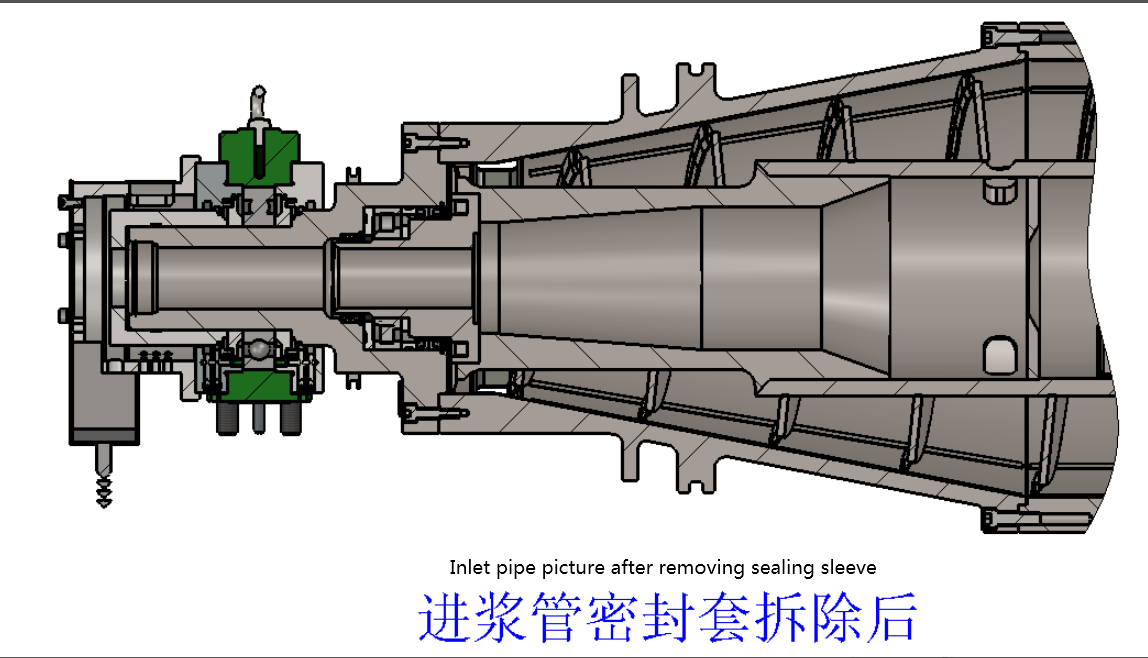

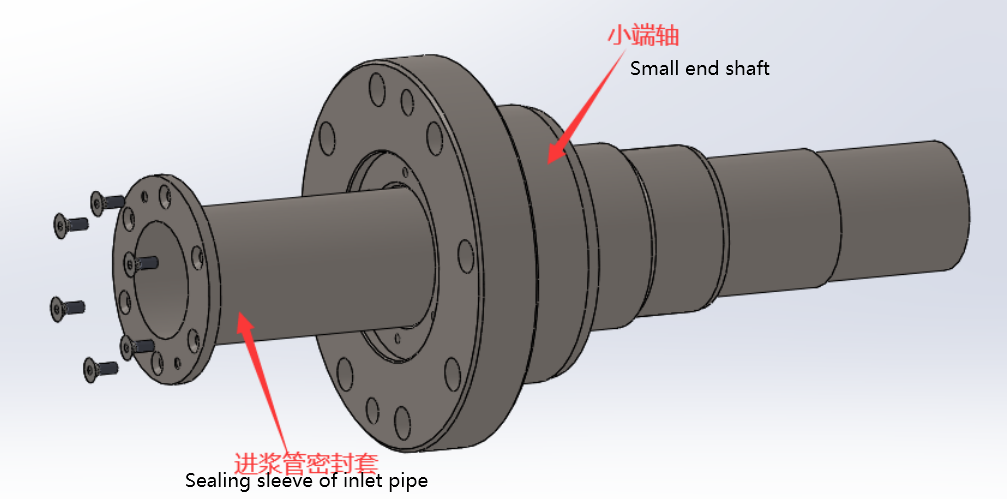

According to the photos client provided, the abraded place is sealing sleeve part of inlet pipe,and we guess the sealing sleeve was also damaged. In order to prevent the new slurry inlet pipe from being damaged again, the damaged sealing sleeve needs to be removed, and the removing of sealing sleeve will not affect the functionality of decanter centrifuge. After the sealing sleeve is removed, the gap between inlet pipe and the rotating parts will be increased, which will prevent the friction between inlet pipe and rotating part .

The specific steps for removing the sealing sleeve:

1.Remove the motor shield, take off the auxiliary motor belt, open the upper cover of the collection box, unscrew the mounting bolts of the centrifuge bearing seat, pull out the positioning pins. Use the sling to lift the centrifuge assembly and place it on a flat floor covered with rubber sheets or V-shaped sleeper. The component of centrifuge assembly can not be in contact with the ground to prevent damage the surface of the part and the mating surface。

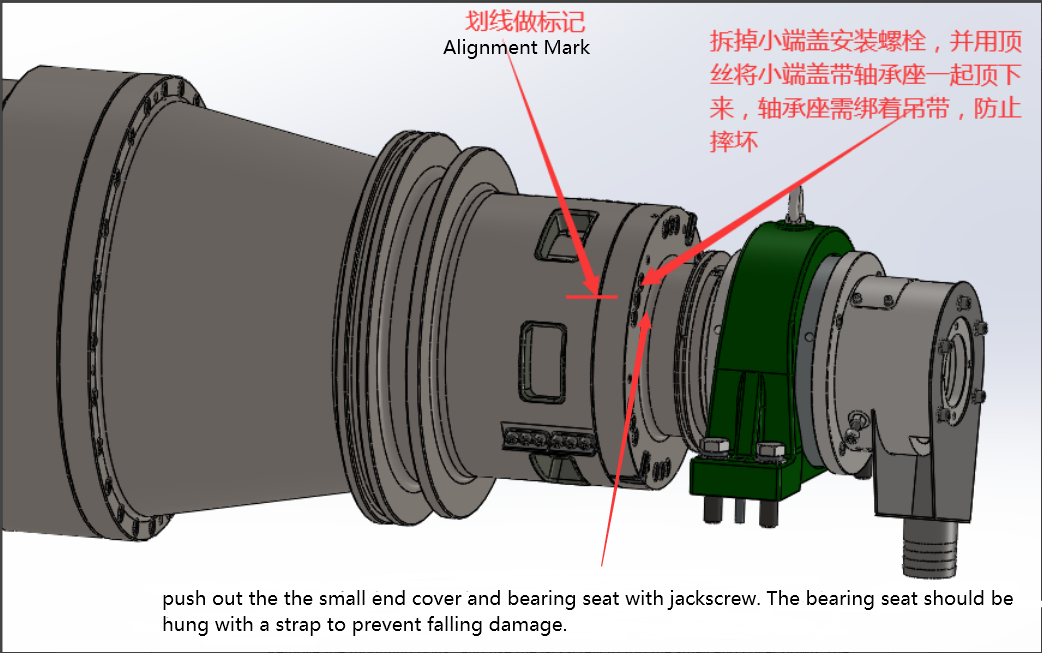

2. Make alignment marks on the small end cover and the rotating drum, then unscrew the mounting bolts of the small end cover, push out the the small end cover and bearing seat with jackscrew. The bearing seat should be hung with a strap to prevent falling damage. The disassembled small end cover should be wrapped with plastic film to prevent dirt from falling into the bearing chamber.

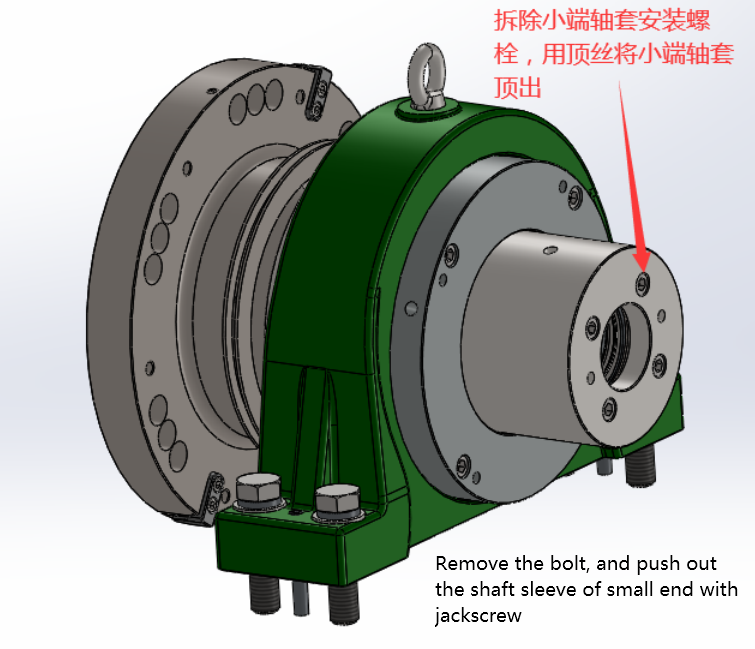

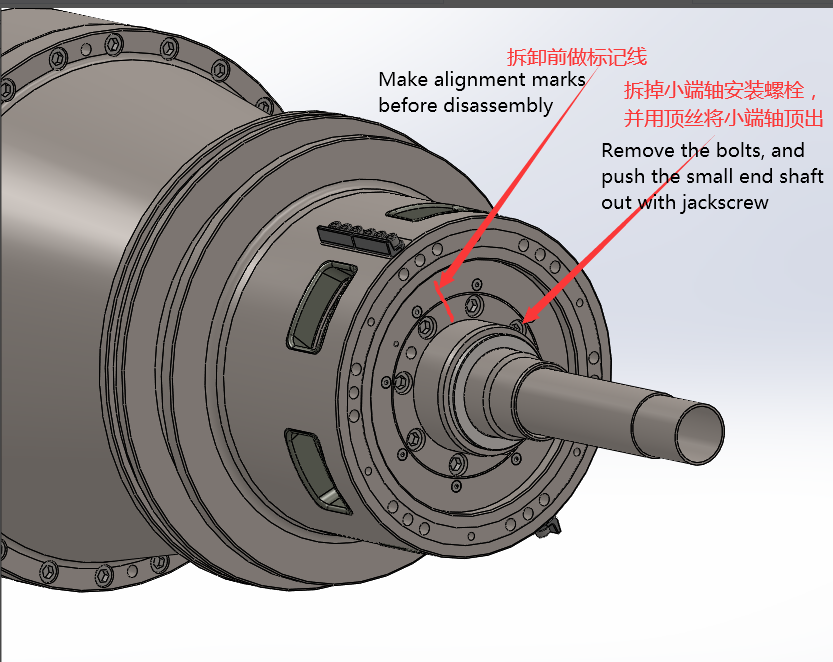

3. Unscrew themounting bolts of small-end shaft , and push out the small-end shaft with jackscrew.

4. Remove the seal sleeve of the inlet pipe installed in the small end shaft, check and clean the material in the spiral mandrel, then align the small end shaft with the mark line before, assemble the small end shaft. Pay attention to check the spigot surface, use the fine oil stone polish the burrs and the bulge caused by the jackscrew during disassembling.

- Details

-

Published: 03 March 2021

GN has been in the solids control industry for more than 13 years. We never stop to develop new equipment to help our customer impression the drilling efficiency ,and reduce the cost. As we all know there will produce large drilling cutting and other waste solids in the oil field when drilling. We need to transfer these waste into other place immediately to make room for the constantly discharged drilling cutting from shale shaker or decanter centrifuge. Most of oil field use the screw conveyor for these material transferring. But the screw conveyor only can transfer in straight direction , if there is a elbow transfer ,we have to add other screw conveyor. This will occupy much area at job site and also limited on the transfer distance.

GN drill cutting transfer pump is developed for the high solids material transfer. Difference with screw conveyor, there are two hydraulic rod to inject the material into the pipe, and then push it, complete the the solids transferring. The transfer distance of this pump can reach 100 meters in horizontal and the vertical height can reach 30meters. And the max particle size the pump can transfer is 20mm. GN drilling cutting transfer pump is automatic, we designed a catch hopper, the discharged drilling cutting from shale shaker can directly feed into the hopper, and then be transferred.

We have 3 models according to the transfer capacity , the 15A for 10 tons/hour, 22A for 20tons/hour, and the 30A for 30 tons/hour. Long transfer distance and small occupation space are the advantage to other kinds pump. The solids pump even can transfer 100% dry powder material, but for now, we only used it for drilling industry. Sample mechanical structure , easily maintain and stable quality , that will make sure the drilling cutting transfer pump will instead of screw conveyor someday. If your project have demand on our equipment , welcome to contact us. We will be pleased to quote and provide the technical support.

- Details

-

Published: 19 February 2021