As we all know there will produce large waste in the drilling process. Especially in the oil well drilling job site. Some well depth can reach 7000 meters,it need last of drilling mud to take out the cutting from oil well, balance the well pressure, cool the rig tap. Drilling mud is very important and complex material, and also withe high pollution to the environment .It is cycle using , the solids control system can remove out the most particle in the mud , and get the clean liquid for reuse. The discharged solids not only include the drilling cutting, but also include many high pollution mud material . As normal ,these kind material is very hard to treat and speed lots of money. Actually ,there is no technology to reduce these material pollution in zero. So GN solidfication unit is used to solidify these pollution to prevent the pollution spread and go deep into ground pollute the water.

From the photo you can see ,this solidfication unit is a very sample structure, include the feed hopper, catch hopper, mix tank. The cutting will be transferred by the screw conveyor, and feed into mix tank through the feeding hopper. Must times , we use the cement as the curing agent. The worker can directly dump cement to tank through the catch hopper. Then the drill cutting and cement will be mixed inside the tank through a agitator. And then discharge out the tank. After few times, then cement and drill cutting will be solidify together.

After treatment , these material can be used to built road as the base. Or deeply bury. However we do not need to worry the pollution spread , because the pollution material is locked together with cement. GN Solidfication unit has 15m3/hour treatment capacity. And if you need more bigger size, we are also can customized production. Solids control and waste treatment both are the two main business, if you have the demand on our equipment , please feel free to contact us.

- Details

-

Published: 09 February 2021

Solids control is one branch industry of drilling. In petroleum industry,oil well drilling is a complex project. As usual, the depth of well can reach 7000 meters. The drilling need mud to take out drill cutting from well and also balance the well pressure. GN has been in solids control equipment for more than 15years. We are the first China manufacture that got the API test report for all API code screen, and all our solids control equipment are comply with API standard. For now, we had funded our Houston branch to serve the America client , and Russia branch to serve the area that speak Russia. Last week we delivered 1 set solids control system to our European client. It will be matched with 1000HP rig machine.

The 1000 HP rig usually be used to rig the well less than 1000meters . Which have not too strict requirement to drill mud. As you can see from the photo, the system just include the shale shaker and decanter centrifuge. Shale shaker can remove out most big size particle, and if we use more higher API screen, the smallest particle size that we can remove is 44 um. That is very tiny particle. In this system we didn’t not add any desander and desilter, because the 1000 HP has a small require to the mud flow. If we want to get more cleaner mud, we just need to start the decanter centrifuge. The decanter centrifuge can separate out the particle between 20-40um.

In this system ,our engineer designed small size mud tank. Which is convenient for client to transport it into different job site and also easily to install. All the electrical control and electrical motor are comply with ATEX explosion proof standard to reach the European standard. Stable quality with competitive price, especially the design capacity and customized production are our advantage to serve will our client. If you have demand on solids control equipment, welcome to contact us.

- Details

-

Published: 02 February 2021

TBM is short of tunnel boring machine, which is one kind big equipment for the tunnel excavation. It is widely used in the subway tunnel ,and some other traffic project. When boring tunnel, the rig temperature will raise quick and also there will be lots of drilling cutting in the front of rig machine. So this machine need to use drilling mud to flush the drill bit for cooling. And also the mud will take out the drilling cutting out tunnel. As usually,the TBM project need large water, if we do not treat these mud. It will be series pollution and waste water.

Last week we delivered one desander and one GN decanter centrifuge for the TBM project. This desander was equipped bottom shaker. When the slurry feed into hydrocyclone, the liquid will be separated out under the separation force, and the solids will down to bottom shaker. The shaker could generate more than 7 G force with high frequency of vibration. The contained liquid and solids will be separate and follow into the mud tank.

As usually,the desander only can treat the particle bigger than 60 um, the TBM require the liquid as much clear as better. So we add the decanter centrifuge for further separation. GN 453 decanter centrifuge has be exported to many countries and served TBM project , which capacity is 60m3/hour. Decanter centrifuge is one kind equipment that utilize the G force that generated under the high rotated speed to reach the solids liquid separation. As we all know, the solids density is bigger than water. When the material bear big G force, the different density solids and liquid will separate layers, the bottom solids and top layer of liquid. Mud after decanter centrifuge , the solids content of discharged liquid will less than 5%, which is totally can be reuse for TBM.

GN has been in separation for more than 15 years. We have full experience and stable quality , if you you interest in our separation equipment , please contact us , we will be pleased to provide technical support.

- Details

-

Published: 27 January 2021

With more then 15 years development ,GN Decanter centrifuge has developed several series for different application. At the beginning of GN history, we main served drilling company for the drilling mud treatment. Actually Decanter centrifuge has widely application in different country. GN T series is spec developed for the material dewatering.

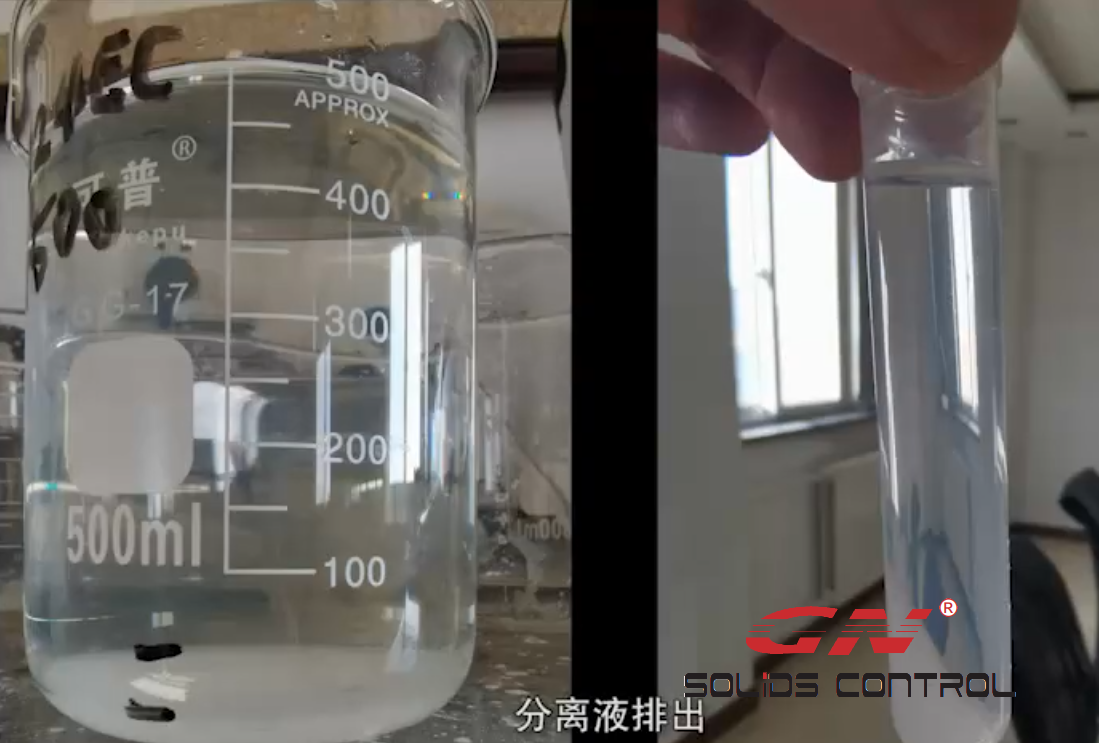

As the client requirement, we made the experiment of mineral salt separation. This client want to got the solids salt as much dryer as possible. According to client the material parameter that our client provided, we mixed the same liquid with same solids content. From the photo we can see, the discharged white solids is dryer enough and it reached the requirement of our client. The discharged water is also clear enough for reusing.

GN C series decanter centrifuge have vanity model according to the treating capacity. They are 224,364,454,554. The treating capacity from 6m3/hour to 120m3/hour. Client can choose they model according to the quantity they will treat. 224 series is the most popular model with the mini size and low maintaining fees. Our Decanter centrifuge used the double stainless steel for centrifuge assemble to improve anti-wear and lifetime. In the solids discharged port, installed the tungsten carbon steel to prevent the abrasion from solids. Decanter centrifuge is one kind of high speed equipment, the rotated speed can reach 5000 rpm, the balance is the big challenge for manufacture, which required high accuracy. Every centrifuge assemble will pass 3 balance testing, include the dynamic balance. The high manufacture accuracy and strictly balance test can make sure the machine is the beast work state when delivery to our client.

The mineral salt separation is just one kind application. Decanter centrifuge can treat most material that need solids liquid separation. Through the centrifuge force generated under the high rotate speed, solids and liquid will bear different G force and finish the separation. If you have project need Decanter centrifuge ,welcome to contact us. We can make the separation experiment for you and share our experience.

- Details

-

Published: 20 January 2021

With the development of GN, we have accumulated lot of experience and technology about the solids-liquid separation. Not only drilling mud treatment,but also some other industries such as food industry, beverage industry, biological material extraction, waste water treatment etc. Decanter centrifuge and other solids control equipment as our featured machine, which has stable quality and get good feedback from our client. But most time the shale shaker,mud cleaner are used to treat the mud with high solids content ,and it can not be used in food industry. GN Screw press dewatering machine are developed for low solids content material treatment. Last week we delivered out GNDN-202 model screw press to Peru for the food material dewatering.

Screw press utilize reduce the space and press the material to reached the dewatering purpose. The main body of the screw press sludge dewatering machine is a filtration device composed of fixed ring and moving ring, in which the screw axis runs through. The

front section is for concentration and the back section for dewatering. The filtering gap formed between the fixed ring and the moving ring of the dewatering screw press and the pitch of the screw axis gradually decreased from the concentration section to the dewatering section.The rotation of the screw press shaft pushes the sludge from the concentration section to the dewatering section,through reduce the gap to press the material and dewater the sludge.

As usually, Screw press dewatering is good performance to treat the material that solids content less than 5%, for some tiny particle, we suggest to add flocculant to combine the tiny particle into big. Which can help to get the best separation effect.

Compare with decanter centrifuge, screw press is energy-saving , it has low electric consumption, and it is very suitable to treat some material with soft solids. We have several modes that capacity from 0.5m3-52m2/hour, if you want to know more about our screw press dewatering machine, please feel free to contact us.

- Details

-

Published: 12 January 2021