GN Solids Control, a global leader in the development and production of solid-liquid separation equipment, has achieved a significant milestone in its journey by relocating to a new state-of-the-art factory in Yutian. After 15 years of dedicated growth and development, GN Solids Control has expanded its presence to over 80 countries, servicing thousands of diverse projects in various industries.

Since its inception, GN Solids Control has been at the forefront of innovation in the field of solid-liquid separation technology. Initially serving the oil and gas drilling industry, the company has since expanded its product applications to serve sectors such as mining, water treatment, waste management, and conveyor equipment.

The decision to move to a new facility became imperative as the existing factory could no longer meet the growing demand for GN's cutting-edge products. The newly inaugurated Yutian factory covers a vast area of 800,000 square meters, providing an extensive and advanced production space. Equipped with the latest manufacturing technology and efficient management practices, the new facility ensures shorter lead times and even more consistent equipment quality.

"This move marks a significant turning point in our company's history. We've come a long way in the past 15 years, continuously improving and expanding our product line to meet the evolving needs of industries around the world. The Yutian factory allows us to work even more efficiently, deliver products faster, and maintain a higher standard of quality."

The expansion to the new factory reflects GN Solids Control's commitment to providing the best solid-liquid separation equipment and technology to its global customer base. The advanced facility will enable the company to further its mission of serving a wide range of industries with top-tier equipment and solutions, ensuring environmental sustainability and operational efficiency.

The move to the new factory is not only a remarkable milestone for GN Solids Control but also a testament to the company's dedication to excellence, innovation, and customer satisfaction. As they embark on this exciting new chapter, GN Solids Control is poised to continue its remarkable journey of growth, providing superior solutions for a rapidly changing world.

- Details

-

Published: 20 October 2023

City, Date - In a recent milestone, a European client received ATEX certified equipment from GN Solids Control, a renowned provider of solid-liquid separation solutions for the oil and gas industry. The delivery included GNZYQ1000A and GNZCQ270B equipment, both designed to effectively remove unwanted gases from drilling fluids.

GNZYQ1000A, the first-stage separation device, plays a crucial role in eliminating gas contaminants in drilling mud. Meanwhile, GNZCQ270B, employed after the vibrating screen, offers secondary gas separation.

The presence of gases in drilling fluids can have adverse effects on fluid density and overall performance. In some cases, these gases may even be flammable or toxic. Consequently, the removal of gas contaminants is essential for ensuring a safe and efficient drilling process.

GN Solids Control's equipment is highly regarded for its compliance with the ATEX directive, a European regulatory framework that sets safety standards for equipment used in potentially explosive atmospheres. The ATEX certification ensures that the equipment can be safely operated in environments where explosive gas mixtures may occur.

The GNZYQ1000A and GNZCQ270B are engineered to meet the stringent safety and performance requirements of the European market. This successful delivery underscores GN Solids Control's commitment to providing innovative and compliant solutions to its global client base.

Drilling operations in Europe and beyond can now benefit from the enhanced safety and performance offered by GN Solids Control's ATEX certified Poorboy Degasser and Mud Gas Separator equipment. By efficiently removing gas contaminants from drilling fluids, these devices are pivotal in safeguarding personnel and equipment while optimizing drilling efficiency.

GN Solids Control is a leading provider of solid-liquid separation solutions for the oil and gas industry. With a commitment to innovation and safety, the company offers a comprehensive range of equipment designed to meet the evolving needs of the global drilling industry. ATEX certified equipment is just one example of GN Solids Control's dedication to providing state-of-the-art solutions for its clients.

- Details

-

Published: 13 October 2023

The Water Environment Federation Technical Exhibition and Conference, known as WEFTEC, is an annual event that brings together professionals from the water and wastewater industries to showcase the latest technologies, share knowledge, and explore innovative solutions. In 2023, this prestigious event took place in Chicago, USA, attracting participants from across South America, North America, and Asia. The primary focus of WEFTEC is to address the challenges related to wastewater treatment, emphasizing the importance of environmental protection and resource conservation.

GN Solids America LLC, a leading player in the field of solid-liquid separation and waste management equipment, was an active participant at WEFTEC 2023. This international platform provided an excellent opportunity for GN Solids America LLC to connect with a diverse range of customers and engage in discussions about wastewater treatment technologies.

One of the highlights of this event was the chance to reconnect with longstanding customers, fostering relationships and exploring potential collaborations for upcoming wastewater treatment projects. These interactions reinforced GN Solids America LLC's commitment to providing efficient and sustainable solutions to its clients.

At WEFTEC 2023, GN Solids America LLC showcased a range of cutting-edge equipment, including screw press dewatering machines, decanter centrifuges, and solids vacuum pumps. Among these, the screw press and solids vacuum pump garnered significant attention from the attendees.

The screw press dewatering machine is a state-of-the-art technology that effectively separates solid and liquid phases in wastewater, offering enhanced efficiency and reduced operational costs. Its compact design and user-friendly features make it a valuable addition to any wastewater treatment system.

The solids vacuum pump, on the other hand, is an innovative solution for transporting and handling solid materials in a liquid medium. Its robust performance and versatility make it ideal for a wide range of industrial applications, further underscoring GN Solids America LLC's commitment to sustainability and environmental protectioIn conclusion, GN Solids America LLC's participation in WEFTEC 2023 was a resounding success, as it allowed the company to connect with both existing and potential clients, showcase its state-of-the-art equipment, and explore collaborations for future wastewater treatment projects. The company remains dedicated to advancing technologies that contribute to environmental protection and resource conservation, reaffirming its position as a leader in the field of solid-liquid separation.

- Details

-

Published: 06 October 2023

In recent years, GN Solids Control, a leading manufacturer of decanter centrifuges, has witnessed a surge in customer appreciation for its centrifuge technology and manufacturing expertise. This growing acclaim can be attributed to the diverse range of applications that GN centrifuges are being utilized in, including a recent project involving the separation of Kava powder using the GNLW224 decanter centrifuge.

The GNLW224 decanter centrifuge is a testament to GN Solids Control's commitment to innovation and precision engineering. With a compact 9-inch diameter and high rotational speed, this centrifuge has earned a reputation for its reliability and efficiency. We will explore its successful application in the overseas Kava powder suspension separation project.

To tackle this intricate separation task, GN Solids Control's GNLW224 decanter centrifuge was deployed. This centrifuge was specifically chosen for its compact design and high-speed operation, making it ideal for processing suspensions with fine particles like Kava powder.

Compact Size: The 9-inch diameter design is space-efficient and allows for easy integration into existing production lines or facilities.The GNLW224 boasts a high rotational speed, which enhances its sedimentation efficiency and facilitates the separation of fine Kava powder particles from the liquid suspension.

Stable Operation: The centrifuge's stable operation ensures consistent and reliable separation performance, minimizing downtime and maximizing productivity.

The GN GNLW224 decanter centrifuge's successful application in the overseas Kava powder suspension separation project showcases its versatility and efficiency in handling challenging separation tasks. As GN Solids Control continues to accumulate centrifuge technology and manufacturing experience, clients can expect even more innovative solutions to meet their specific needs across various industries.

With GN Solids Control's commitment to excellence and continuous improvement, the GNLW224 decanter centrifuge stands as a reliable choice for separation challenges, making it a preferred solution for industries seeking precision and efficiency in their operations.

- Details

-

Published: 29 September 2023

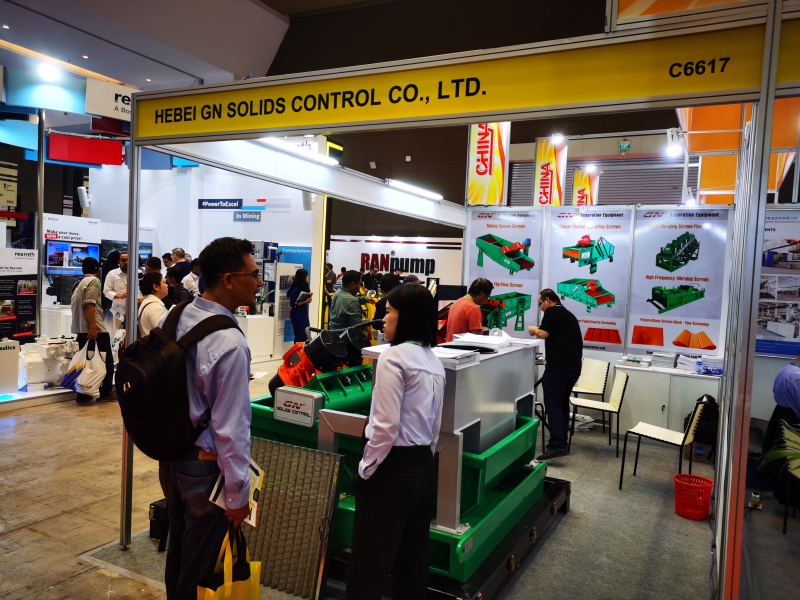

GN Companypresence at the 2023 Indonesia Exhibition for Mining and Oil Industry with a remarkable display of innovative products. The exhibition showcased a wide range of offerings, including medium-sized linear screens, large banana screens, multi-layer vibrating screens, tailings dewatering centrifuges, solid vacuum pumps, and petroleum solids control equipment such as drilling fluid vibrating screens, horizontal screw centrifuges, and drilling fluid shale shakers.

During the exhibition, GN Company's booth emerged as a major attraction, drawing the attention of numerous visitors seeking cutting-edge solutions for Indonesia's mining and oil industries.

One of the highlights of GN Company's participation in the exhibition was the opportunity to reconnect with long-standing clients. This provided a platform for technical discussions and knowledge sharing, allowing GN Company to introduce new separation technologies to their valued customers. The exhibition also facilitated discussions with both existing and potential clients, laying the foundation for future collaborations.

The medium-sized linear screens and large banana screens exhibited by GN Company garnered particular attention for their efficiency in mineral processing and solid-liquid separation. The multi-layer vibrating screens offered superior performance in separating various materials, making them a versatile choice for the mining industry.

Additionally, the tailings dewatering centrifuges and solid vacuum pumps demonstrated their effectiveness in handling challenging slurry and waste management tasks. GN Company's petroleum solids control equipment, including drilling fluid vibrating screens, horizontal screw centrifuges, and drilling fluid shale shakers, showcased their ability to optimize drilling operations and reduce environmental impact.

As the exhibition concluded, GN Company left a lasting impression on the attendees, reinforcing its position as a leader in providing innovative solutions for the oil industries. The interactions with clients, both old and new, set the stage for promising partnerships, and GN Company remains committed to advancing technology and driving progress in these vital sectors.

In conclusion, GN Company's participation in the 2023 Indonesia Exhibition for Mining and Oil Industry exemplified its dedication to excellence, innovation, and customer engagement in the ever-evolving landscape of mining and petroleum industries.

- Details

-

Published: 22 September 2023