GN Solids Control is a leading manufacturer of shaker screens, it’s headquarter is located in China. Now GN Solids Control has two main manufacturing factories. GN Solids Control provides over 5000 pieces of various shaker screens every month. GN No. 2 factory has finished building last year, many automatic CNC machines are moving to the GN new factory. With the opening of this new factory, GN will be able to manufacture over 15000 pieces shaker screens every month.

As the oil price keeps going down, many large drilling companies are using GN shaker screens to cut cost. GN manufactures many different types of replacement shaker screens, which includes replacement Derrick 500 and Derrick 2000 series, Swaco Mongoose screens, NOV King Cobra or VSM300 series, FIS screens. All GN replacement screens are effectively used to replace those above screens with a very good separating performance while the price is very low, drilling companies can save up to 50% compare to using the original screens.

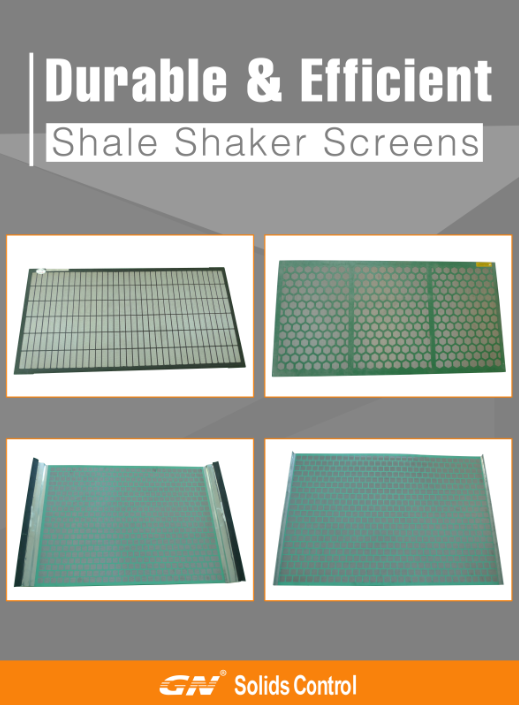

GN cutting edge CNC machines manufacture various shaker screens and keep a good consistency. GN screens include metal frame screens and composite frame screens. With the usage of GN No. 2 factory, GN Solids Control will provide more and more composite material shaker screens. The manufacturing cost of composite shaker screens are higher than metal frame screens, but their separating performance and using life is much better than the metal frame screens.

- Details

-

Published: 22 January 2016

GN Solids Control is one of the largest solids control and drilling waste management manufacturer. Besides those large equipments, GN Solids also manufacture many replacement shaker screens for world famous shale shakers.

Last year, GN Solids Control built another factory which is quite close to GN headquarters. GN NO.2 factory will manufacture more shaker screens by using more advance CNC machines. Before GN Solids Control can provide over 5000 pieces shaker screens every month, with the opening of the No.2 factory, GN Solids Control will be able to provide over 15000 pieces shaker screens every month.

GN No.2 factory will manufacture shaker screens with automatic machines which will help to keep the quality more steady. Most of the shaker screens will be composite material shaker screens. Due to the excellent working performance and good quality, GN composite material shaker screens are more widely accepted compared to the metal frame shaker screens.

Composite material shaker screens have larger screen area as the supporting frames are less than the metal frame ones. And the weight is much lighter for composite material shaker screens.

Now most of the well know shaker screens GN Solids Control can provide replacement ones for them. Shakers such as Derrick FLC 500 series, 2000 series can use GN replacement 500 PMD, 500 PWP and 200 PMD, 2000 PWP screens. Some other shakers such as MI-SWACO Mongoose screens are also widely used. Besides, NOV King Cobra, VSM 300 shakers can also use GN replacement screens.

- Details

-

Published: 15 January 2016

GN Solids Control manufactures many different kinds of shaker screens which can be used on competitor’s shale shaker directly. With these years onsite feedback, GN Solids Control has kept upgrading GN shaker screens in order to have a better separating performance and longer life.

GN replacement shaker screens are including GN steel frame shaker screen and GN composite frame shaker screen if you divided them by materials. These replacement screens can be used on Swaco Mongoose shaker, NOV or King Cobra Shaker, Fluid System Shaker, Derrick Shaker etc.

GN pretension shaker screens for shaker GNZS594 are very convenient to mount. Those 4 pieces shaker screens are fixed by GN patented wedges, which can be punched out by hammer and can be easily done by one worker.

GN screens have been exported to more than sixty countries due to remarkable cost-effective. Screens are widely used for oil and gas drilling or HDD drilling. Since the oil price went down last year, many drilling companies have been trying to cut cost, GN shaker screens are always the best choice for them.

GN solids control has some regular clients; they keep purchasing shaker screens from us every month, sometimes GN ship several 40 feet containers to them as it helps to save shipping freight. For large clients, GN Solids Control also provides some discount based on the purchase quantity.

As a branch company of GN Solids Control, GN Solids America LLC has a large warehouse located in Houston, various shaker screens are in stock for fast delivery. We also make the stock plan several months ahead of real purchase for those regular clients in order to provide a better lead time.

In 2016, GN new branch factory will manufacture more shaker screens. Welcome to visit GN Houston warehouse and check our huge shaker screens in stock.

- Details

-

Published: 08 January 2016

The Start

It starts from POLLUTION. It starts people / government finally realised that the earth, the land, the water, what they live, or the living based on have been destroyed. Then late but rather than none, law comes, to list the standard we should follow, the limit of deposit we can dump. In China, seems they also realised that it is already too late for protecting the environment, the law is quite strict on the drilling waste management, the standard is even higher than other developed countries. Drilling fluid have been list in the quite dangerous fluid, and the fluid after treatment have to comply with the waste water recycle regulations. Though the technique now in China is not developed that well, it is already a big step.

The Main Equipment

The main and initial equipment including Hi-G shaker, Verticle cuttings dryer, and decanter centrifuge. For most of the applications, if water based mud, the first step is collect all the drilling cuttings from shale shaker, mud cleaners to the Hi G shaker. If oil based mud, then to the vertical cuttings dryer. Then fluid after these two equipment will be pumped to the decanter centrifuge.

Hose Pump, Screw Conveyor, are normally used for transferring the solids / drilling waste from one stage to another stage, depends on the drilling site arrangement. GN Solids Control is offering modular transferring solutions.

The Better Solution

Except the basic solution, if need better result, cleaner fluids, cleaner water, dryer solids, which can be dumped or reused. Then the other intrestesting equipment will be used.

Dewatering system

Normally used after or before the decanter centrifuge, to improve the result from the decanter centrifuge, if after the centrifuge in drilling waste management progress then also need another decanter. GN Solids control have the containerised dewatering unit as optional offer.

Solidification

For water based drilling waste, the final step for solids is dump, normally. Then solidification is also a normal choice, GN solids control is offering the solidification unit which have been used for a lot of the site.

TDU Thermal Desperation Unit

If more complex drilling waste management site, especially when we need recycle water, oil, and reuse solids waste, then the TDU will be a good option, as that what she will do. GN Solids Control is testing it in 2016, and will face the world soon. Keep tune.

- Details

-

Published: 05 January 2016

On the rig site, if you ever see the big giants, except rig itself, then you can find mud tanks, surrounding the rig, and catching eye sights. While all the professionals know that, though it is not just a steel box, or a simple container, still have a lot of engineering work. It is definitely not deserve to spend several times money for them to travel all the world. Nowar days, as oil price goes down, the market is being more and more quiet than before. Saving/ economic purchasing is more important then ever before. And if possible to fabricate good tanks locally, will definitely change the situation, and being competitive.

So if you are a tank supplier, pls feel free to get in touch with GN.

Recently GN have sent a full set solids control equipment to Russia, which contains:

1) 4 sets of shale shaker, GNZS594E-HB.

This shale shaker is 4 panel shakers with big treating capacity, working performance equivalent to USA brand shakers. The vibration motor can be 1.72kw /1.94kw for option, G force is adjustable by adjusting the eccentric block inside of the vibration motor.

2) 2 sets of decanter centrifuge, GNLW363CG

The client buy two sets of same model centrifuge GNLW363CG for easier operation and less spare parts stock. The centrifuge is high speed centrifuge can reach 3200RPM, and G force 2062@3200RPM. We can also match lower speed pulley with belt per client's request.

3) 20 sets of centrifugal pump

For Russia market, this is not the first time we cooperated with local tank suppliers, there are several companies like GN products, and doing the fabrication sometimes refer to GN designs.

For other countries, we also have a lot of tank suppliers working as partners for projects. And some of them we are working even closer to do marketing etc.

- Details

-

Published: 10 December 2015