Increase your environmental friendly drilling efficiency with GN products, one of the most important equipment is the Solidification / Stabilisation unit. The drill cuttings solidification unit is advanced and unique, which is quite flexible comparing the waste cuttings solidification plants.

Solidification – Is an absorption process where contaminants, typically oils, are taken into the absorbent material in the same way a sponge takes on water. In general, solidi cation is the addition of absorbents such as soil, y ash, kiln dust, cement, clays or sawdust to the drilling waste. The solidi ed product will have improved properties such as strength, compressibility and a reduced permeability.

Stabilisation – Is an adsorption process whereby contaminents are electrochemically bonded to the stabilising agents. Contaminants that are stabilised within the matrix are less likely to be released into the environment. This process is particularly relevant to the stabilisation of heavy metals and oils that would otherwise be rapidly available to the environment through leaching.

The adeptness to coalesce or stabilise a accurate decay beck and the e ectiveness of the analysis is abased on the decay blazon and analysis reagent factors. Typically, adumbrative samples of the decay are class activated to actuate the a lot of acceptable conception above-mentioned to eld implementation. Selection of the conception is commonly based on key belief such as leachate superior and backbone of the nal product.

Solidification and stabilisation generally requires the use of specialised accessories and actinic reagents. The processes absorb signi deceit abstracts administration upstream and after of the bond unit. Some decay streams may accommodate contaminants that can arrest the solidi cation/stabilisation processes.

For the solidification / stabilisation action to yield abode it is important to carefully adviser the decay produced at the rigsite for levels of alkali baptize and oil. This will advice to minimise the use of reagents and optimise the process, thereby abbreviation costs and the ecology impact.

Thus, it is with the accomplishment and ability that Scomi Oiltools has developed over the endure 20 years that allows us to, accommodate safe, amount e ective and environmentally complete solidi cation and stabilisation processes.

- Details

-

Published: 10 December 2015

GN Solids Control Co., Ltd continues to be production shale shakers, mud cleansers, desanders, desilters, decanter centrifuge, cuttings dryers and mud systems for since the institution. Most of GN solids control and drilling waste management systems are using outside China and taiwan, which are using in around 60 countries.

GN Solids Control equipments have been improving since the establishment. Every year, GN engineers modify and update their solids control in addition to drilling cuttings management devices to treat OBM, WBM as well as SBM aiming for a better in addition to better result.

GN companies various shale shakers with regard to using in different worksites, for instance oil and gas drilling, horizontal going, dredging, mining etc . Over these usages, GN also offers shakers for diamond going or core drilling.

GNZS752E-DM is one of the most popular shakers to split up mud in diamond going. This type of shaker is pretty lightweight and convenient to move. Typically, the diamond drilling as well as core drilling are mainly applying small equipments which can be brought be a helicopter. Because the majority of the drilling sites is miles away from urban area and also there’s barely no highway to transport these equipments having a truck.

GN 752 shaker is mainly used in the stone drilling or core going for remote areas. Often the treating capacity is two hundred GPM which can meet the majority of the demands. There are only a couple of pieces of shale shaker screens put together on this shaker. The weight is simply 893 kg.

In order to fulfill the demands of the weight limitation for shakers, GN shale shakers can be modified by simply disassembling shaker bottom or even feeding box. The sto? motors are world famous companies such as Martin or OLI. G force is also flexible (usually it’s 7. one G).

GN Solids Control also provides mini decanter centrifuge to separating out and about finer solids after addressed by GN mini shaker. GN mini decanter centrifuge has a 9 inch spinning bowl. Rotating speed actually reaches to 4500 RPM to be able to separating finder solids.

- Details

-

Published: 07 December 2015

It is very strange that China even have more strict environmental requirement on the dredging field than all over the world, on the waste solids disposal and also the fluid dump, no matter how it have been applied on field, in paper it is really advanced. So basically when the oil market is down, we get a chance there, some client in dredging field said. Just like you have done in waste management field. Also we have realised that not only china all over the world, people are taking more care on the environmental protection. For dredging, what we need is:

Recycle the cleaner fluids.

Dump and reuse as much as possible on the solids.

Not like the oil gas drilling, from the pond, or from the river, from sea, there are sands, rocks, and other things as you can imagine which have been buried in it. So the separation seems very different. Except the basic concepts.

Separate the biggest particles and other stuff other than the sands and silts. There are many ways to do this, one is dig another pit / pond, with at big screen from where dredging pump feeds, let the screen separate unreasonable parts to the pond, keep them away from the progress. Another way is gumbo box, it is quite same as the mining applications, to separate the biggest rocks from the first step, then others feeding directly to the shale shaker.

Then directly, or by another pump from the pond. The feeding goes to the double deck shaker. In GN, it is GNZS706E, which is good to separate the bigger sands and the most of the bigger solids. going through two sieves.

Catched by the pump, feeding to the cyclones, to get the silts separated.

Then in the same way, separated by the decanter centrifuge.

Sometimes it also need help from chemicals that why a flocculent unit is there. To concentric the small particles to be bigger ones, then easier to be separated.

Kindly contact GN for a full solution.

- Details

-

Published: 29 November 2015

It is another productive year, a big order knocks the door of this. In the beginning, EMEC, our partner from Egypt, after taking time to test our centrifuges, finally come to GN from US suppliers, they purchased about 40 centrifuges in total, and the first one is more than 30units.

Then as we all know, oil price keep going down, market is down. We are holding the project, the project has been delayed is the most often answer we heard from client.

Good news is the Chinese government published the new environmental protection regulations. We need handle the drilling waste. Which makes half of the market live again. While thanks to the seed we have planted, GN have been in study of the vertical cuttings dryer and other driving waste management equipment long time ago. Which makes, again, GN stand in front of all Chinese manufacturers, to supply the high quality waste management products to the local market.

A few dozens vertical cuttings dryer, decanter centrifuges, and dewatering unit have been sent to the Chinese drilling site.

So as the old saying, when the flower blooms outside of the wall, the people inside can smell, the big Chinese contractors finally comes to GN, finally realised and found the best equipment supplier here. One of the best.

Another benefit also thanks to the down time market, more and more Europe or US contractors finally get more and more interested in good quality Chinese suppliers. Since this could be one way to save cost. If can supply same quality with more competitive price, why not keep themselves in the perception of made in China. A lot of people have gave it a try. Maybe you all also should do.

After Baker Hughes choose GN products, more and more big players in the market comes to us, come to our yard, comes to our site, they want to find out what makes Baker feedback that these products even better than US/ EU products.

- Details

-

Published: 23 November 2015

GN Solids Control is a recognized solids control and drilling waste management manufacturer in both home-based and outside China. And Shale Shaker is one of GN Solids Control’s most popular goods in all of GN merchandise line. Each year, GN makes in addition to sells around 250 pieces of GNZS series shale shakers to more than 62 countries and regions of the globe.

GN Shale Shaker Positive aspects:

1 . GN owns twelve patents, most of them are on shale shaker design, and such effective remedies are important to ensure the shaker to present reliable performance without seeping.

2 . GN use Malta Oli brand vibrating engines. For normal models such as GNZS594E and GNZS703E, often the G force for vibrating sex is up to 7. 5, flexible. When talking about High-G blow drying shaker GNZS594HGE-LD, the penis-shaped G-force could reach main. 0.

3. In order to thoroughly stand the high vibrating push from the vibrating motor, often the shale shaker has to be built with a substantial structure. That’s why GNZS series shaker’s deck are made from Stainless Steel.

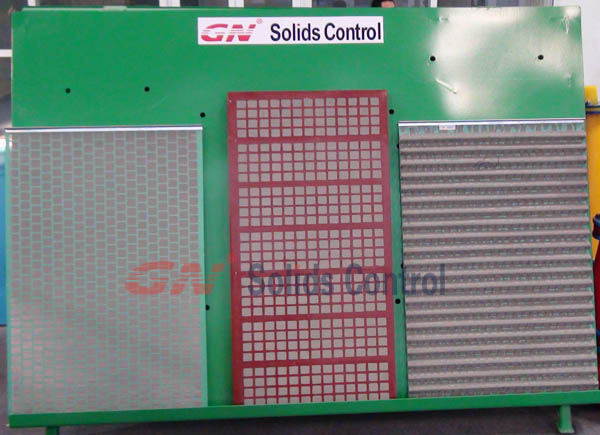

But the good shale shaker is not the only factor to completely show the performance, which is also impacted greatly by the shaker window screens. In order to better control shaker screen’s quality, GN features a separately shaker screen manufacturing plant for supporting GN individual shakers. But since GN displays is very cost-effective, lots of GN clients who already have additional brands’ shakers source window screens from GN. GN would make replacement screen of good good quality and reasonable price with regard to old and new clients, and in addition customizes shaker screens with basis of a MOQ.

The reason why choose GN screens?

- reliable quality and sufficient service life. Because GN Solids Control alone is also shaker manufacturer, GN is more familiar with screens and also knows how to make suitable window screens for shakers.

2 . constantly improving the producing procedure, with proper procedure in addition to methods in making screens, GN screens’ quality is always elevating.

3. good material. GN uses imported glue in addition to based on the mesh center regarding China.

Seeing is thinking, welcome to visit GN and offer trial orders on GN screens.

- Details

-

Published: 18 November 2015